With the continuous advancement of industrial technology, residual stresses increasingly impact the performance, service life, and application domains of metallic materials.

Residual stress is the internal stress remaining after loading, caused by temperature, phase, or microstructural changes.

Residual stress affects mechanical properties and can cause deformation, cracking, or failure, making its control and mechanism study crucial.

Analysis of Residual Stress Formation During Heat Treatment

To understand the formation of residual stresses during heat treatment, it is essential to examine the mechanisms that generate internal stresses.

Among these, thermal stresses arising from uneven temperature distributions play a key role, as they directly influence the stress state within the material. The following section focuses on the formation of thermal stress and its relationship with temperature gradients.

Formation of Thermal Stress

Relationship Between Temperature Gradient and Stress Distribution

Temperature gradients during heating and cooling cause uneven expansion or contraction, generating internal stresses. During heating, faster surface expansion than the interior creates surface tension and internal compression.

During cooling, faster surface contraction causes surface compression and internal tension. Temperature gradients during heat treatment alter surface and internal stress distribution.

Rising temperature increases surface expansion, while slower interior heating causes uneven strain and stress buildup. At critical temperatures, phase transformations change the microstructure and increase internal stress complexity.

During cooling, faster surface contraction and slower interior shrinkage create strain differences that drive stress evolution.

Generation and Effects of Phase Transformation Stress

Temperature changes during heating or cooling cause asynchronous phase transformations, altering volume and generating phase transformation stress.

This is particularly evident during quenching, where rapid cooling causes volume expansion during the transformation from austenite to martensite.

Phase transformations occur over a broad temperature range, causing unsynchronized changes and complex stress distributions.

Phase transformation stresses depend on the transformation type, material properties, temperature, and rate. Austenite-to-martensite transformation expands volume, creating localized stress concentrations due to uneven transformation.

Temperature gradients cause the surface to transform before the core, creating large surface-core stress differences. Phase transformation expands the volume, inducing internal tension and surface compression.

Cooling rate affects phase transformation stress: rapid cooling causes high stress peaks, while slow cooling produces smaller stresses.

Evolution of Microstructural Stress

Microstructural stress arises from phase transformations and changes, affecting both microstructure and macroscopic stress.

Heat treatment induces microstructural transformations, like austenite to martensite or pearlite, causing volume changes and lattice distortions.

Non-uniform volume changes from microstructural transformations create complex internal stresses. Microstructural transformations contribute to stress through internal stresses from volume changes, influenced by transformation magnitude and phase distribution.

For example, martensite occupies a larger volume than austenite, so when austenite transforms into martensite, the overall volume of the material increases.

Asynchronous phase transformations cause uneven volume changes, generating significant internal stresses.

Furthermore, differences in the elastic modulus and thermal expansion coefficients between the phases also exacerbate stress formation.

Residual Stress Control Strategies During Heat Treatment

Effective control of residual stresses during heat treatment is critical to ensure material performance and prevent defects. One of the most influential factors is the quenching process, which directly affects temperature gradients and the resulting stress distribution. The following section discusses strategies to optimize quenching for residual stress reduction.

Optimization of Quenching Processes

Selection and Control of Cooling Media

When selecting cooling media, material properties, workpiece geometry and dimensions, and performance requirements must all be considered.

Water is widely used for quenching due to its high cooling efficiency, rapidly reducing workpiece temperature. Rapid water cooling can create steep temperature gradients, causing high residual stresses and possible cracking.

Adding coolants or using step-cooling controls stress by moderating the cooling rate. Oil cools slower than water, ensuring more uniform temperature and is ideal for hardenable steels or complex workpieces.

Gases, often under high pressure or as jets, provide controlled cooling for workpieces needing precise dimensions and surface quality.

Optimizing Temperature and Holding Time

Temperature and holding time control phase transformations, microstructure, and stress evolution, making their precise regulation key to optimized quenching.

Quenching temperature affects transformation and stress: higher temperatures enhance austenite conversion but raise thermal stress. Too low a quenching temperature can hinder austenite transformation, yielding incomplete phase changes and subpar material properties.

Quenching temperature should stay within the material’s austenitizing range to ensure uniform transformation and minimize residual stresses.

Proper holding time ensures uniform temperature before quenching, reducing stress from temperature differences during phase transformation.

Short holding time causes uneven temperature, incomplete transformation, and higher stress concentration. Excessive holding time aids temperature uniformity but promotes grain growth, reducing toughness and mechanical properties.

Therefore, optimizing holding time should prioritize minimizing duration while ensuring complete austenitization, thereby preventing excessive grain growth.

Tempering and Stabilization Treatment

Tempering and stabilization reduce residual stresses from quenching, improving toughness, microstructure, and dimensional stability.

Proper tempering temperature and time relieve residual stresses, reducing brittleness and fracture risk. Optimal tempering temperature ensures stress relief without causing new microstructural changes.

Low tempering transforms martensite into tempered martensite or ferrite, gradually relieving stresses and improving toughness.

Too low tempering may leave high residual stresses, reducing material performance.

Conversely, higher tempering temperatures, while more effective at stress relief, may induce grain growth, thereby reducing material strength.

Tempering temperature should ensure full stress relief without excessive softening or grain growth.

Tempering holding time ensures uniform temperature, enabling complete microstructural transformation and stress relief.

In this process, stress release and microstructural transformation occur simultaneously within the material. Holding time should be optimized to relieve stress while preserving hardness and strength.

Stabilization treatment is essential for reducing residual stresses and enhancing dimensional stability, typically applied to materials after tempering.

Low-temperature or multiple tempering cycles stabilize retained austenite and release residual stresses, enhancing dimensional stability.

Cryogenic treatment converts residual austenite to martensite, then re-tempering relieves stress, enhancing stability, wear, and fatigue resistance.

Experimental Validation

To verify the effectiveness of the residual stress control strategies, a series of experiments were conducted. The following section details the experimental setup, including material selection, specimen preparation, and quenching parameters.

Experimental Conditions and Parameter Settings

Experimental Material and Initial State

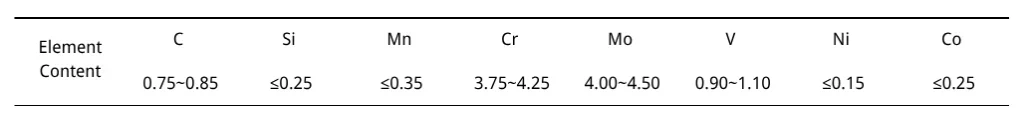

M50 steel, shown in Table 1, was used in rolled-annealed condition with a pearlite–ferrite microstructure.

Prior to the experiment, the M50 steel specimens underwent quenching to transform their microstructure into martensite, facilitating subsequent testing.

The specimen dimensions were Φ45×60mm cylindrical, ensuring uniform stress distribution throughout the test.

Quenching Process

M50 steel was quenched at 850–900°C using segmented heating with 30-minute soak and 8°C/min rate. To prevent oxidation of the specimens, the heating process was conducted in a vacuum furnace.

Tempering Process

Tempering aimed to relieve quenching stresses and optimize strength and toughness, using 450–500°C for 2.5 hours over 1–3 cycles.

Residual stress release was evaluated by varying tempering cycles, temperatures, and times; specimens were air-cooled afterward.

Stabilization Treatment Process

We investigated the residual stress evolution in M50 steel during thermal cycling using a two-step process of cold and heat treatment.

The study conducted cold treatment in liquid nitrogen to convert residual austenite into martensite, reducing residual stresses.

We heated the specimens at 400°C in a nitrogen furnace after cold treatment and observed stress changes at different cold temperatures.

Results Analysis

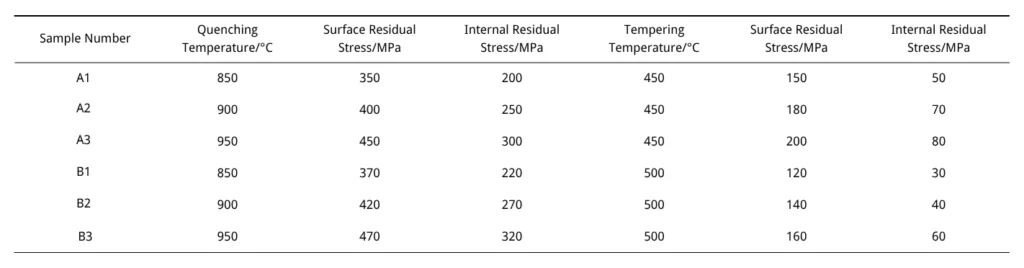

The experimental results are shown in Table 2.

Increasing the quenching temperature intensifies phase transformations, leading to higher surface compressive and internal tensile stresses (see Table 2).

This trend confirms that rapid cooling at high temperatures induces significant phase transformation stresses.

Residual stress analysis shows tempering effectively reduces stresses in the material.

Stress decreases significantly as higher tempering temperatures more fully relieve surface compressive and internal tensile stresses.

In Sample A1 tempered at 450°C, surface and internal stresses dropped sharply, showing tempering efficiently relieves residual stress.

In Sample B3, increasing tempering from 450°C to 500°C reduced surface and more significantly internal stresses.

Higher tempering temperatures enhance stress relief, improving overall material performance.

Conclusion

Research on residual stresses offers insights into material behavior and methods to improve quality and lifespan.

Future studies will integrate microstructure and macroscopic behavior to develop precise residual stress prediction models.