Stainless steel resists corrosion from air, steam, and water, while acid-proof steel resists chemical corrosion from acids, alkalis, and salts.

Due to compositional differences, stainless steel may not resist chemical corrosion, while acid-proof steel is generally rust-resistant; corrosion resistance depends on alloying elements.

Typically classified by metallographic structure:

Generally, metallographic structure classifies common stainless steels into three categories:

Austenitic stainless steel, ferritic stainless steel, and martensitic stainless steel.

These three microstructures gave rise to duplex, precipitation-hardening, and high-alloy stainless steels with under 50% iron.

Austenitic Stainless Steel

This type features a face-centered cubic (FCC) austenitic microstructure (γ phase) as the primary matrix.

It is non-magnetic and primarily strengthened through cold working (which may induce some magnetic properties).

The American Iron and Steel Institute designates these with 200 and 300 series numbers, such as 304.

Ferritic Stainless Steel

The matrix primarily consists of a face-centered cubic crystal structure ferritic structure (a-phase), which is magnetic.

Generally, heat treatment cannot harden it, but cold working can slightly strengthen it. The American Iron and Steel Institute designates these with 430 and 446.

Martensitic Stainless Steel

The matrix consists of a martensitic structure (body-centered cubic or cubic), is magnetic, and can have its mechanical properties adjusted through heat treatment.

The American Iron and Steel Institute designates these grades with numbers such as 410, 420, and 440. Martensite exhibits an austenitic structure at high temperatures.

When cooled to room temperature at an appropriate rate, the austenitic structure transforms into martensite (i.e., hardening).

Austenitic-Ferritic (Duplex) Stainless Steel

Features a matrix comprising both austenitic and ferritic phases, with the minor phase typically constituting over 15% of the matrix.

It is magnetic and can be strengthened through cold working. Grade 329 is a typical duplex stainless steel.

Compared with austenitic stainless steel, duplex steel has higher strength and much better resistance to intergranular, chloride stress, and pitting corrosion.

Precipitation-Hardening Stainless Steel

This type features an austenitic or martensitic matrix and can be hardened through precipitation hardening treatment.

The American Iron and Steel Institute designates these grades with 600 series numbers, such as 630 (equivalent to 17-4PH).

Generally, austenitic stainless steels exhibit superior corrosion resistance beyond basic alloys. Ferritic stainless steels are suitable for low-corrosion environments.

For moderately corrosive conditions requiring high strength or hardness, martensitic stainless steels and precipitation-hardening stainless steels are appropriate.

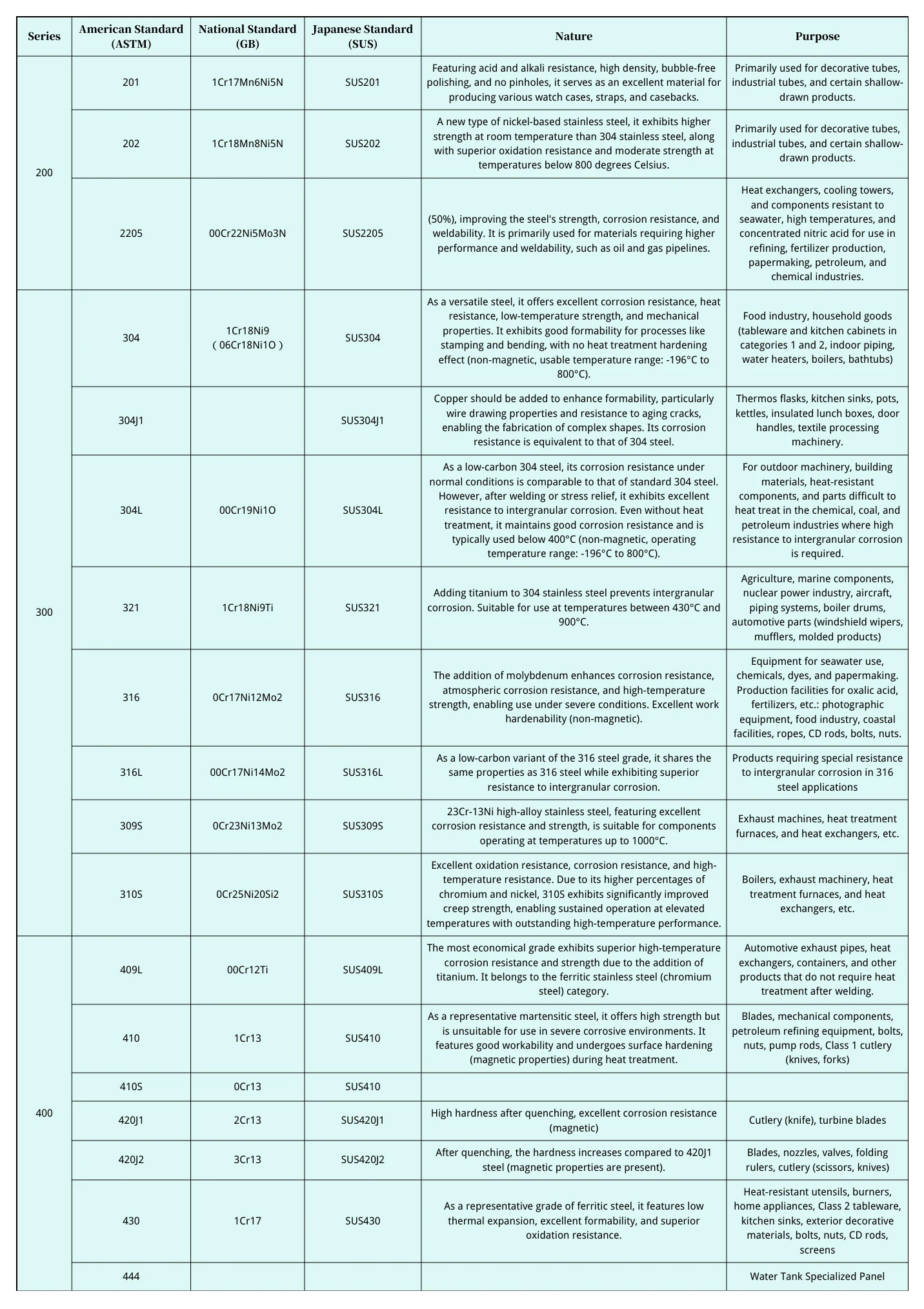

Properties and Applications

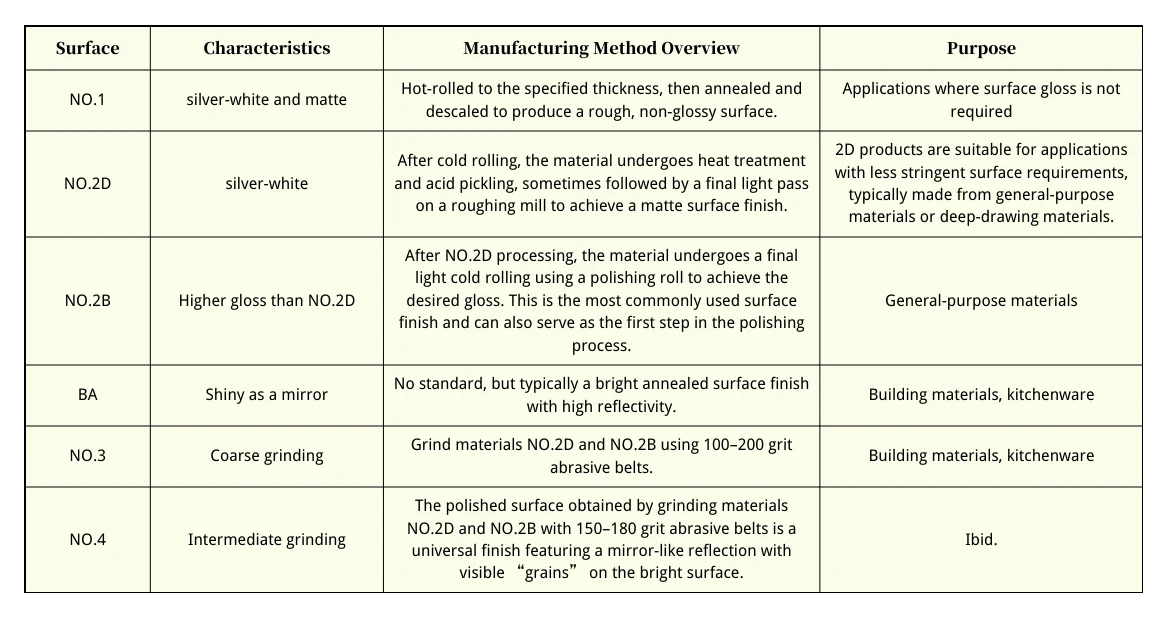

Surface Finishing

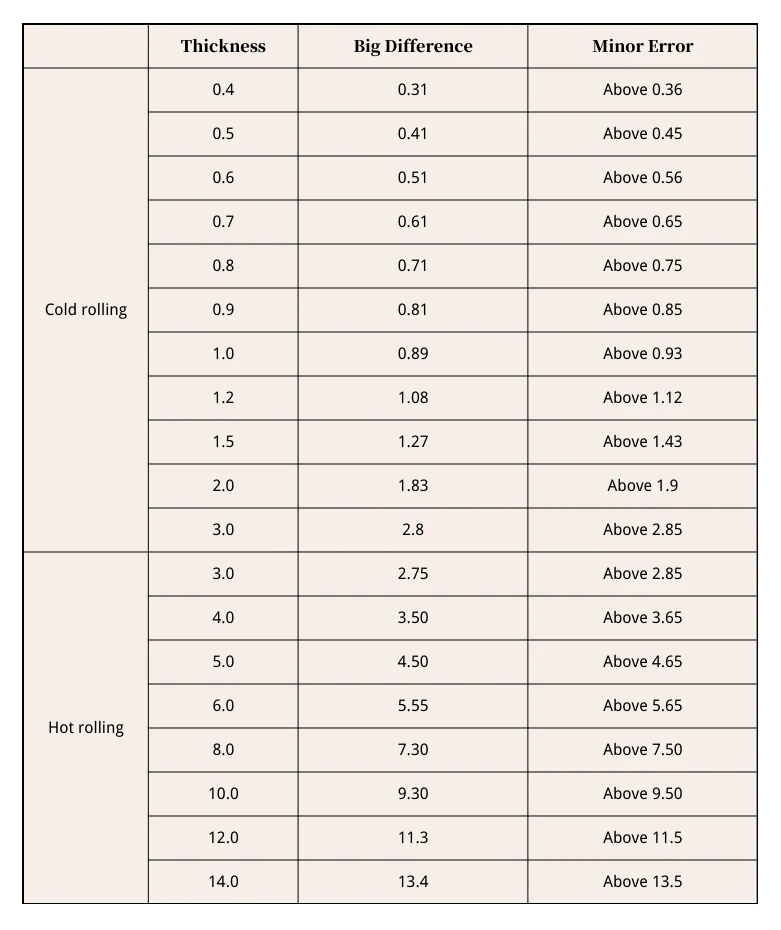

Thickness Classification

Rolling makes plates thicker at the center and thinner at the edges; standards measure thickness at the plate head center.

Tolerances are categorized as large or small based on market and customer requirements. For example:

Three primary factors influence stainless steel corrosion:

Alloy element content

Generally, steel containing 10.5% chromium exhibits low susceptibility to rust. Higher chromium and nickel content enhances corrosion resistance.

For instance, 304-grade stainless steel contains 8%–10% nickel and 18%–20% chromium, making it resistant to rust under normal conditions.

The smelting process employed by manufacturers also impacts corrosion resistance.

Large stainless steel mills use advanced technology and processes to precisely control alloy elements, remove impurities, and regulate billet cooling.

Consequently, their products exhibit stable quality, superior internal integrity, and reduced susceptibility to rust.

Smaller mills often fail to remove impurities during smelting, producing rust-prone products.

External environment: Dry, well-ventilated climates are less prone to rusting.

Conversely, areas with high humidity, prolonged rainy periods, or environments with high acidity/alkalinity in the air are more susceptible to rust.

Even 304 stainless steel can rust if exposed to severely unfavorable surroundings.

How to treat rust spots on stainless steel?

Chemical Methods

Apply acid-based rust remover to re-passivate the surface and restore corrosion resistance with a chromium oxide film.

After acid treatment, thorough rinsing with clean water is essential to remove all contaminants and acid residues.

After all treatments, repolish with polishing equipment and seal with polishing wax. For minor localized rust spots, wipe with a 1:1 mixture of gasoline and engine oil using a clean cloth.

Mechanical Methods

Sandblasting, glass/ceramic microbead shot blasting, immersion cleaning, brushing, and polishing.

Mechanical methods may remove contaminants introduced by previously applied materials, polishing compounds, or immersion solutions.

All contaminants—especially foreign iron particles—can become corrosion sources, particularly in humid environments.

Therefore, a formal cleaning protocol should ideally perform mechanical surface cleaning under dry conditions.

Mechanical methods only clean the surface and do not alter the material’s inherent corrosion resistance.

After mechanical cleaning, operators should re-polish the surface with polishing equipment and seal it with polishing wax.

Common Stainless Steel Grades and Properties for Instrumentation

- 304 stainless steel is a common austenitic grade used for deep-drawn parts, pipelines, vessels, structures, and non-magnetic or cryogenic equipment.

- 304L stainless steel is an ultra-low-carbon austenitic grade that prevents Cr₂₃C₆ precipitation and offers much better resistance to intergranular corrosion than 304.

With slightly lower strength than 321, manufacturers mainly use it for welded corrosion-resistant equipment and instrument housings without post-treatment.

- 304H Stainless Steel. A sub-branch of 304 stainless steel with a carbon content of 0.04% to 0.10%, offering superior high-temperature performance compared to 304 stainless steel.

- 316 Stainless Steel. Based on 10Cr18Ni12 steel with added molybdenum, it exhibits excellent resistance to reducing media and pitting corrosion.

Its corrosion resistance in seawater and various other media surpasses that of 304 stainless steel, making it primarily used for pitting corrosion-resistant materials.

- 316L Stainless Steel. An ultra-low-carbon steel with excellent resistance to sensitization-induced intergranular corrosion.

Suitable for manufacturing thick-section welded components and equipment, such as corrosion-resistant materials in petrochemical facilities.

- 316H stainless steel, a 316 variant with 0.04–0.10% carbon, offers superior high-temperature performance.

- 317 stainless steel has better pitting and creep resistance than 316L, used for petrochemical and organic acid-resistant equipment.

- 321 stainless steel, titanium-stabilized, resists intergranular corrosion and performs well at high temperatures, used mainly in specialized applications.

- 347 stainless steel, niobium-stabilized, resists intergranular corrosion and serves in thermal power and petrochemical equipment.

- 904L stainless steel, with 24–26% nickel and <0.02% carbon, resists non-oxidizing acids and crevice and stress corrosion.

It resists sulfuric acid below 70°C and acetic/formic acid at any condition; formerly a nickel alloy (ASME SB-625), it’s now stainless steel.

China has a similar grade, 015Cr19Ni26Mo5Cu2, while some European manufacturers use 904L for critical parts like E+H flow meter tubes and Rolex watch cases.

- 440C stainless steel is a martensitic grade, the hardest of hardenable stainless steels (HRC 57), used for nozzles, bearings, and valve components.

- 17-4PH stainless steel, a martensitic precipitation-hardening grade (HRC 44), offers high strength, hardness, and corrosion resistance up to 300°C.

It resists atmospheric and mild acid or salt corrosion like 304 and 430, and is used for offshore platforms, turbine blades, and valves.

Conclusion

Stainless and acid-proof steels are versatile materials defined by their composition, structure, and processing.

Austenitic, ferritic, and martensitic steels form the foundation of stainless steel classifications, while duplex, precipitation-hardening, and high-alloy grades expand the options for specialized requirements.

The corrosion resistance of stainless steel depends on alloying elements, smelting quality, and environmental conditions, while proper surface treatment and maintenance help prevent localized rusting.

Various grades, from widely used 304 and 316 to specialized steels like 904L, 440C, and 17-4PH, offer tailored combinations of strength, hardness, and corrosion resistance suitable for instrumentation, petrochemical, thermal power, and high-temperature applications.

Understanding the distinct properties and appropriate applications of each grade ensures optimal material selection, performance, and longevity in both standard and demanding environments.