In intelligent manufacturing, complex mechanical systems face significant control challenges. Multi-axis linkage control emerges as an advanced solution, coordinating the motion of multiple actuators to achieve highly precise and efficient operations. This paper delves into its principles, key technologies, and applications, aiming to enhance the performance of complex mechanical systems and explore its potential for improving manufacturing precision, efficiency, and reliability.

Basic Principles of Multi-Axis Linkage Control Technology

Definition and Characteristics

Multi-axis linkage control is an advanced control technology that precisely coordinates the synchronized motion of multiple actuators within complex mechanical systems. This enables operations with high precision, efficiency, and flexibility. The technology can achieve sub-micron positioning accuracy, significantly boosting processing efficiency and adapting to diverse production needs, thereby providing robust technical support for intelligent manufacturing.

Control System Architecture and Composition

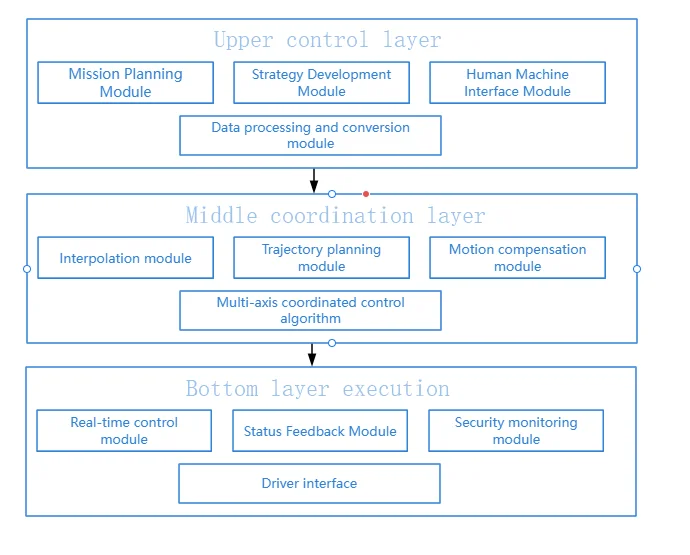

As Figure 1 illustrates, multi-axis linkage control systems typically employ a hierarchical architecture. This includes an upper control layer for task planning, an intermediate coordination layer for orchestrating multi-axis motion, and a bottom execution layer for real-time control. The system primarily comprises controllers, drives, sensors, and actuators. This hierarchical and modular design ensures excellent scalability and ease of maintenance.

Figure 1: Multi-axis linkage control system architecture

Kinematic and Dynamic Model Analysis

Kinematic and dynamic models form the theoretical bedrock for designing multi-axis linkage control systems. These models describe the geometric relationships and motion laws among system components and account for factors like mass and inertia concerning the system’s motion state. They provide important support for advanced functionalities such as trajectory planning, error compensation, and adaptive control, making them key to achieving high-performance multi-axis linkage control.

Key Technologies of Multi-Axis Linkage Control Systems

Precision Positioning and Motion Control

Precision positioning and motion control are central to multi-axis linkage systems, directly influencing processing accuracy and efficiency. In practical applications, engineers widely use high-precision encoders and high-resolution sensors to continuously monitor each axis’s position and speed, ensuring precise positioning.

Feedback Control and Optimization Algorithms

Feedback control and optimization algorithms play a vital role in multi-axis linkage systems. They effectively address external disturbances, changes in system parameters, and multi-objective optimization problems by integrating technologies such as high-gain observers, adaptive control, iterative learning control, and model predictive control.

Real-time Monitoring and Fault Diagnosis

Real-time monitoring and fault diagnosis are essential for ensuring the reliable operation of multi-axis linkage systems. In modern intelligent manufacturing environments, multi-sensor fusion technology commonly integrates data from various sources, including vibration, sound, temperature, and current.

Application Examples of Multi-Axis Linkage Control Technology

Application in Robotics

Multi-axis linkage control technology sees extensive use in robotics, significantly enhancing robot performance and flexibility. For example, a multi-axis industrial robot, as shown in Figure 2, achieves complex spatial movements through multi-axis linkage control.

Figure 2: Multi-axis industrial robot

Application in CNC Machine Tools

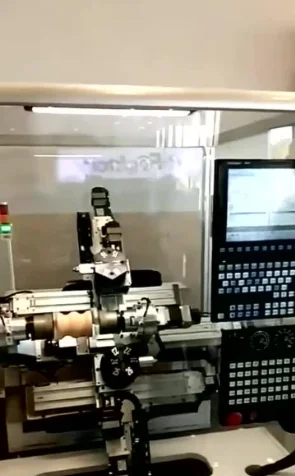

CNC machine tools represent a classic application of multi-axis linkage control technology, leading to substantial improvements in machining accuracy and efficiency. Figure 3 illustrates a multi-axis CNC machine tool. In a five-axis linkage machining center, multi-axis linkage control enables intricate spatial movements of the tool relative to the workpiece.

Figure 3: Multi-axis CNC machine tool

Application in Automated Production Lines

Within automated production lines, multi-axis linkage control technology facilitates efficient and precise collaborative operations. Figure 4 showcases multi-axis automated equipment. For instance, in an automobile body assembly line, the linked control of multi-axis robots and the transmission system ensures the continuity and accuracy of the assembly process.

Figure 4: Multi-axis automation equipment

Conclusion

Multi-axis linkage control technology holds immense potential within the field of intelligent manufacturing. Through in-depth research into its principles and innovative applications, it has significantly improved the manufacturing accuracy, production efficiency, and system reliability of complex mechanical systems.