Since the 1970s, global manufacturing has transformed fundamentally, driven by IT, turning a stable market into a dynamic, evolving global environment.

To meet fast-changing market demands and boost competitiveness, DFM (Design for Manufacture) technology emerged.

DFX, covering all product lifecycle stages, was proposed by SMTA in the 1990s and is widely used across industries.

Recently, DFM research grew; an expert analyzed its system in cycloidal reducer design, focusing on key processes.

Experts proposed a manufacturing-oriented design method and built a prototype system using sheet metal parts.

Another expert detailed DFM use in simulation/digital hybrid design and deep submicron tech for parameter analysis and optimization.

A manufacturability analysis system for rotating parts was developed, defining key functions and technologies for a practical DFM system.

An expert developed software to quickly assess formed parts’ manufacturability, identify costly features, and reduce part costs.

Manufacturing and assembly design methods are now widely used; Boothroyd and Dewhurst methods quantify feature manufacturability.

In electronic design, experts stress manufacturability by following standardized requirements for circuit design.

Integrated circuit design was an early adopter of automated DFM analysis, which is also highly applicable to machining.

Experts used DFMA software to estimate mold costs by adjusting projected area, enabling early assessment in mold development.

An expert proposed a parallel DFM, DFA, and process control method using axiomatic design for early manufacturability.

Experts applied early DFM in parallel engineering and casting to improve castability, reduce costs, and shorten cycles.

DFM is widely applied in product design and manufacturing, evolving toward proceduralization, automation, and systematization.

Application of DFM Technology in the Field of CNC Machining

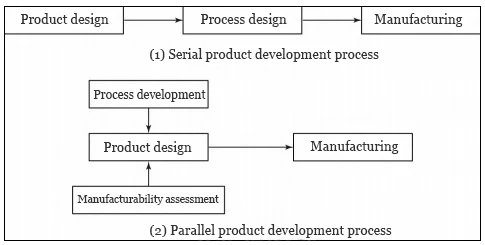

Traditional product development separates design and manufacturing, delaying process design until after structural design.

As mechanical part design grows complex, sequential processes cause costly, wasteful design changes and extend timelines.

Modern parallel development assesses design and manufacturability together, resolving issues early and avoiding changes.

The two development processes are illustrated in Figure 1.

Mechanical processing risks include time, material, clamping, and shapes; systematic manufacturability research is essential.

Comprehensive DFM in machining enables better raw material selection during design to reduce waste.

Optimize detailed structures to avoid special tools and complex clamping methods, thereby reducing machining time;

Set suitable tolerances and wall thicknesses to optimize manufacturability, as shown in Figure 2.

Traditional manufacturability analysis uses manual checks, risking oversights and leaving many issues for production.

Modifying designs during production incurs extremely high costs and results in significant time wastage.

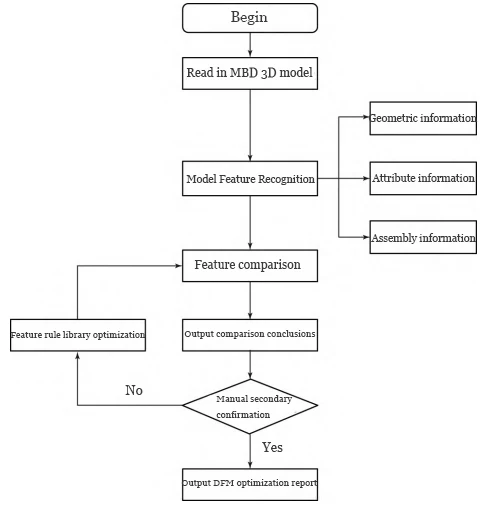

DFM is shifting to early, automated design reviews using MBD models in machining, following this process:

Input the MBD model; DFM software identifies features, checks manufacturability, and outputs results with minimal verification.

DFM requires design–manufacturing integration, with MBD standards ensuring complete geometry, material, and assembly data.

Systematic DFM relies on a feature rule database quantifying manufacturability into standards.

A reliable feature rule library lets automated DFM tools identify features and assess manufacturability.

Creating a reliable, quantifiable rule library requires collaboration and design simulation tools.

DFM relies on simulation tools to convert process needs into quantified design rules.

Second, simulation tools enable virtual manufacturing after DFM changes, visualizing process differences and supporting cost assessments.

Simulation software capable of visualizing manufacturing processes includes tools such as the UG IPW module and casting Moldflow.

Finally, automated DFM tool results still need human review for final judgment.

Human judgment ensures accurate feature identification and rule suitability for stable automated reviews.

Big data enables comparing automated and manual judgments to dynamically update and optimize the rule database.

This is an indispensable step in the early stages of automated DFM assessment implementation or following changes to the rule database.

Application Examples of Automated DFM Technology

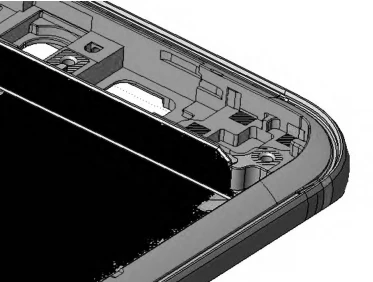

The part shown in Figure 3 is a housing, with the dark areas made of aluminum-magnesium alloy and the gray areas made of PC plastic.

The manufacturing process requires in-mold injection molding to form an iron-plastic composite, followed by milling of detailed features.

The complex features shown can cause overlooked draft angles and milling details in modeling.

Integrating DFM PRO with 3D design software lets users auto-identify injection molding features, generate constraint reports, and review them manually.

After milling design, the rule library inspects features to guide manufacturability optimization and cut development costs.

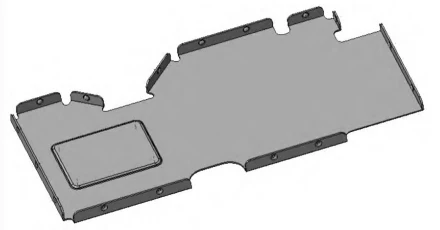

Figure 4 shows a sheet metal part with features requiring strict dimensions to prevent stress and strengthen the die.

By defining feature dimension–thickness equations in DFM PRO, the rule library can optimize sheet metal parts after design.

Other machined parts can have process-based rule libraries, such as assembly rules for interference checks and hole alignment optimization.

turning rule libraries for achieving root radius checks, minimum wall thickness checks, and rotational axis alignment optimization for rotary parts.

Various automated DFM tools show that earlier assessments improve design quality and shorten development cycles.

Current automated DFM tools are limited by lacking reverse design guidance and requiring human intervention.

Advancing technology will broaden the prospects for intelligent, systematic DFM assessment.

Application Prospects of DFM Technology in CNC Machining

DFM in CNC machining identifies manufacturability, prevents design changes, shortens development, and boosts competitiveness.

A hidden advantage of lifecycle DFM is iterative manufacturability across product series, leading to standardized design.

For example, optimizing material selection links processing time to materials, controlling development timelines.

The division and merging of part features significantly impact raw material costs and assembly relationships.

Iterative DFM standardizes design, boosting manufacturability, reusability, and competitiveness while reducing costs and time.

As product development iterates, DFM becomes increasingly integrated into the design phase.

More design tools now include manufacturability modules, integrating DFM directly into the design process.

Comprehensive DFM in mechanical processing requires integrating design and DFM tools to minimize conversions and preserve feature information.

Big data models analyze design and DFM rules to predict issues, give alerts, and speed development.

Conclusion

DFX is a concurrent engineering approach that optimizes product development by addressing all lifecycle requirements early in design.

Computer-enabled DFX tools help engineers design products following DFX principles.

Shorter development cycles boost competitiveness by addressing manufacturing risks in the design phase.

This paper shows automated DFM improves manufacturability, standardizes design, ensures continuity, and boosts competitiveness.

Additionally, it envisions the potential prospects for optimizing DFM assessment implementation stages based on intelligent data models.