Transportation and equipment manufacturers widely use beading of sheet metal to enhance structural rigidity and strength.

Traditional beading faces material waste, poor mold adaptability, and dimensional instability, limiting precision and flexible production.

This paper proposes a 3D-simulated, laser-detected, CNC-compensated beading method for efficient, precise, single-step forming.

Analysis of Current Sheet Metal Beading Processes

Before detailing the traditional process, it is important to understand the typical challenges and workflow characteristics of sheet metal beading. The process generally involves multiple stages, each with specific equipment requirements and operational steps, which together determine production efficiency and part quality.

-

Traditional Sheet Metal Beading Process Flow

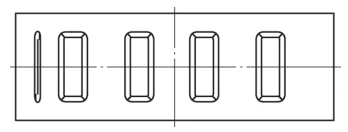

For parts like the one shown in Figure 1, the traditional sheet metal beading process typically involves the following steps:

First, shearing machines cut the raw material into blanks. Then, stamping equipment and specialized dies bead the sheet metal.

After beading, trimming dies or shearing machines perform secondary cutting to remove excess material around the edges.

Some processes also require manual or robotic assistance for loading/unloading to connect the beading and trimming operations.

Producing multi-spec sheet metal parts involves high repetition, heavy mold reliance, and extensive manual handling during transitions.

-

Analysis of Existing Issues

Low raw material utilization: The use of fixed molds for forming and blanking results in ineffective utilization of peripheral scrap, causing significant waste.

Poor mold adaptability: Structural or dimensional changes necessitate costly mold redesigns, increasing production costs and lead times.

Existing processes require extensive secondary handling and loading/unloading, consuming labor and resources, lengthening cycles, and reducing efficiency.

Design and Parameter Calculation of Novel Bead Forming Method

To address the limitations of traditional sheet metal beading, researchers propose a novel method that combines simulation, inspection, and pre-compensated cutting.The following section outlines the overall process flow and the calculation of key parameters that ensure precise and efficient bead forming.

-

Overview of Process Flow

To enhance bead-forming accuracy and efficiency, this paper introduces a workflow that integrates 3D simulation, laser vision, and parameter compensation.

3D Simulation Analysis → Laser Inspection → Compensated Blanking → Bead Forming Verification → Mass Production.

3D Simulation Analysis: A digital model predicts shrinkage and deformation to optimize blank size.

Laser Vision Inspection: A 3D laser scanner captures point clouds to generate edge curves and obtain shrinkage values (ΔL, ΔW).

Compensated Cutting: Symmetric expansion and pattern compensation guide CNC laser cutting to the final shape.

Beading Validation: Conduct forming tests on compensated blanks to verify dimensional accuracy, ensuring single-pass forming without secondary trimming.

Mass Production: Begin batch processing once parameters stabilize and dimensions qualify, with sampling to ensure quality.

This process significantly enhances material utilization, dimensional consistency, and manufacturing flexibility.

-

Theoretical Parameter Calculation

Constant Metal Volume Principle: Despite shrinkage and deformation during beading, the metal volume remains constant.

Therefore, we can derive the blank volume formula from the relationship between metal mass and density: V = m/ρ.

Here, V represents the blank volume, m denotes the sheet metal part’s mass, and ρ is the material density.

This method supports dimensional unfolding. Controlling blank mass and type yields accurate theoretical dimensions.

Formula for Unfolded Area and Dimensions

After determining the volume V of the pressed blank and the material thickness t, the unfolded area S of the blank can be derived as S = V/t.

Based on the workpiece shape characteristics, if designed as a rectangular or square blank, its length L and width W satisfy S = LW. If one dimension is known, the other can be calculated using L = S/W or W = S/L.

These calculations underpin blank cutting. 3D simulation–based models enable automatic parameter extraction and process compensation for laser pattern design.

Width Allowance Coefficient: To account for nonlinear shrinkage, a coefficient K adjusts theoretical length and width to meet final forming requirements.

Correction formula: L = K × L₍theoretical₎, W = K × W₍theoretical₎, with K typically 1.1–1.3, depending on bead depth, material, die, and experience.

Too small K causes short edges and failed dimensions; too large K wastes material.

After 3D simulation and prototyping, K can be set accurately, improving blank design, forming precision, and reducing trimming or rework.

-

CNC Laser Pre-Compensation Strategy

Use a 3D laser vision system to capture edge deformation and extract shrinkage values ΔL and ΔW.

Using the center as reference, shrinkage is symmetrically distributed, and corners are offset by ΔL/2 and ΔW/2 to form A’, B’, C’, D’.

Using the compensated corners and laser-scanned edge curves, mirror symmetry generates a laser cutting pattern with shrinkage compensation.

CNC laser cutting yields tolerance-ready blanks, eliminating trimming and improving efficiency.

Three-Dimensional Visual Inspection and Point Cloud Model Construction

To accurately compensate for dimensional changes during bead forming, the sheet metal workpiece must be precisely measured. The following section introduces the three-dimensional laser scanning system and its role in capturing, processing, and analyzing edge deformation data.

-

Composition of the Three-Dimensional Laser Scanning System

The three-dimensional laser visual inspection system primarily consists of a laser scanner, data processing host, control software, and display terminal.

The scanner non-contact scans the workpiece surface by emitting laser beams, capturing edge point cloud data with high precision and efficiency.

The system offers real-time feedback, ideal for inspecting edge deformation in flanged sheet metal.

With specialized software, it creates 3D models to support compensation analysis and laser cutting.

-

Point Cloud Data Acquisition and Processing Workflow

Point cloud data obtained from laser scanning requires processing to extract valid information.

Initial steps include noise removal and data registration to ensure seamless integration of multi-angle scan data.

Subsequently, edge curve features are extracted, and curvature analysis is performed on the boundary lines.

The output 3D model captures beading shrinkage, providing a reliable basis for accurate compensation design.

-

Edge Shrinkage Data Extraction and Model Feedback Mechanism

From the 3D point cloud, edge deformation curves are extracted to calculate shrinkage ΔL and ΔW versus design dimensions.

The system uses shrinkage data to adjust the blanking pattern, enabling pre-processing correction.

This closed-loop system improves first-pass forming accuracy, eliminates trimming, and boosts manufacturing flexibility.

Conclusion

This paper improves dimensional accuracy of bead-reinforced sheet metal via 3D modeling, laser inspection, and pre-compensated laser cutting.

The method precisely compensates blank dimensions for one-step rib forming, reducing material waste and labor.

This method is versatile, flexible, and suited for multi-variety small-batch production, supporting intelligent sheet metal manufacturing.