Traditional mechanical manufacturing processes have increasingly revealed limitations in meeting complex structural production demands and responding swiftly to market needs.

Amid this, 3D printing provides an additive manufacturing approach, creating new opportunities in mechanical manufacturing.

3D printing enables rapid prototyping of complex structural components, effectively shortening product development cycles and reducing production costs.

In-depth exploration of 3D printing applications and challenges in mechanical manufacturing holds significant importance for driving innovation within the industry.

3D Printing Technology and Its Application Advantages in Mechanical Manufacturing

3D printing is a technology that constructs objects layer by layer using bondable materials like powdered metals or plastics, based on digital model files.

In recent years, it has demonstrated significant application advantages in the mechanical manufacturing sector.

3D printing overcomes traditional limits, enabling complex internal structures and unique shapes for greater design freedom.

3D printing removes molds and complex machining, allowing rapid prototyping from digital models and faster product development.

This advantage is particularly pronounced for small-batch, customized production demands, allowing swift responses to market changes.

3D printing layers materials additively, minimizing waste, improving material use, and lowering production costs compared to traditional methods.

Additive manufacturing enables fast, customized production of mechanical products, fulfilling diverse market needs and enhancing manufacturers’ competitiveness.

Practical Applications

3D printing technology has gradually transformed mechanical manufacturing by offering flexibility, precision, and efficiency across various production stages. Its applications range from early-stage design and prototyping to component production, mold fabrication, and part repair, providing tangible benefits in speed, cost, and customization. Among these, prototype manufacturing is one of the most widely adopted areas, demonstrating the technology’s ability to accelerate product development and innovation.

-

Prototype Manufacturing

Traditional prototypes use slow, costly manual or CNC methods, while additive manufacturing quickly creates accurate prototypes from digital models.

In automotive, 3D printing swiftly produces precise prototypes that match the final product and reveal internal structures for testing.

3D printing prototypes quickly spot design flaws, enabling fast tweaks, shorter development, lower R&D costs, and faster commercialization.

-

Mold Manufacturing

Traditional mold manufacturing is complex, time-consuming, and challenging for intricate molds.

3D printing technology enables direct fabrication of mold cavities, significantly shortening the mold manufacturing cycle.

In injection molding, 3D printing enables quick mold prototypes, which can be refined with post-processing to meet functional needs.

For small-batch production, 3D-printed molds offer advantages of low cost and short lead times.

Using molds with conformal cooling channels improves cooling efficiency, reduces molding cycles, and enhances product quality.

3D printing quickly adapts to frequent mold design changes, reducing modification costs and time.

-

Repair and Remanufacturing

In the field of mechanical repair and remanufacturing, 3D printing technology demonstrates significant potential.

Traditional repair methods for damaged components involve lengthy machining and welding, while 3D printing offers precise, tailored repairs.

Localized damage to aircraft engine blades can be repaired by 3D scanning the area and using 3D printing to restore the blade’s performance.

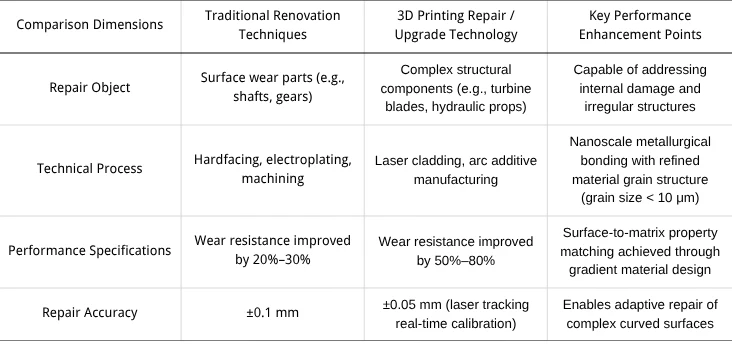

In remanufacturing, 3D printing repairs and upgrades used components to match or exceed the performance of new parts (see Table 1).

This is especially valuable for critical machinery components, reducing production costs and minimizing resource waste.

3D printing can produce replacement parts that match original performance, solving supply issues for aging equipment and extending lifespans.

Challenges Facing 3D Printing Technology in Mechanical Manufacturing

Despite its advantages, 3D printing in mechanical manufacturing faces multiple challenges that hinder its broader adoption.

These challenges span technical limitations, material constraints, incomplete standards, and a shortage of skilled personnel, all of which affect production efficiency, product quality, and industrial scalability.

Among these, technical bottlenecks are particularly critical, directly impacting the precision, speed, and reliability of 3D-printed components.

-

Technical Bottlenecks

Current 3D printing struggles with ultra-high precision, and errors in components like gears and bearings can compromise system performance.

On the other hand, 3D printing is slower than machining, limiting its efficiency for mass production and tight timelines.

Stability is a challenge, as factors such as material properties, equipment performance, and environmental conditions can lead to inconsistent quality and higher defect rates.

For instance, printing large, complex structural components may lead to localized deformation or cracking.

The software and control systems in 3D printing need optimization to handle various materials and complex structures, improving precision and stability.

-

Material Limitations

Currently, 3D printing materials are limited to plastics, metal powders, ceramics, and similar types.

The mechanical industry needs advanced materials, but 3D printing for high-strength alloys, heat-resistant, and biocompatible materials is still evolving.

Moreover, existing 3D printing materials carry high costs, limiting their large-scale production applications.

Material properties and quality can vary between batches, impacting print outcomes.

Developing new 3D printing materials requires time and investment, slowing expansion and performance improvements.

-

Incomplete Quality Standards and Certification Systems

The variety of processes and materials in 3D printing lacks unified quality standards for regulating procedures and evaluating part quality.

Differences in printing techniques, equipment, and materials lead to inconsistent part performance and quality, hindering product consistency and reliability.

Certification systems struggle to evaluate the safety and durability of 3D-printed parts, lowering market acceptance and raising quality concerns.

The lack of authoritative quality inspection bodies raises risks and costs in 3D printing applications.

-

Talent Shortage

3D printing is an interdisciplinary technology combining materials science, engineering, computer science, and IT.

There is a shortage of professionals skilled in both 3D printing and mechanical manufacturing processes.

Higher education programs and curricula are insufficient to meet the market demand for 3D printing talent.

Companies face difficulty recruiting and training 3D printing professionals, with challenges in attracting talent and high training costs.

The rapid evolution of 3D printing demands continuous skill updates, but the lack of training platforms deepens the personnel shortage.

Application Strategies and Development Recommendations

To fully realize 3D printing’s potential in mechanical manufacturing, targeted strategies are needed across technology, standards, talent, and industrial collaboration.

These strategies aim to overcome current limitations, accelerate adoption, and ensure sustainable development. Among them, achieving technological innovation is the foundation for enhancing efficiency, quality, and competitiveness.

-

Achieving Technological Innovation

Technological innovation is key to 3D printing’s role in mechanical manufacturing, advancing materials, processes, and design for digital, high-end production.

Optimizing 3D printing parameters and adding sensor monitoring boosts precision, stability, and quality control.

Second, adopt DfAM to create optimized structures that enhance performance, reduce assembly, and improve efficiency.

Third, leverage AI and big data for automation and predictive maintenance, and integrate 3D printing with CAD/CAM, simulation, and digital twins to drive digital transformation.

Integrating 3D printing with CNC machining and heat treatment enhances accuracy, surface quality, and expands its economic viability in manufacturing.

Build a collaborative 3D printing system with joint labs to drive innovation and commercialization, boosting China’s competitiveness.

Innovation and synergy in materials, processes, and design drive 3D printing’s efficiency and quality in manufacturing.

-

Intensifying Material R&D Efforts

Establishing material R&D platforms is a critical measure to advance 3D printing materials during the technology’s development.

The platform should integrate universities, research institutions, and enterprises into a unified industry–academia–research–application innovation system.

Strengthen materials research to link microstructure, properties, and printing processes, supporting the development of new materials.

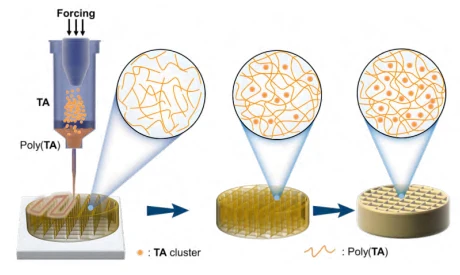

Intensify the development of materials with specialized properties for different mechanical manufacturing sectors, such as polysulfides (Figure 1).

Furthermore, advancing the industrialization of 3D printing materials is vital for enhancing material quality and supply stability.

Governments should implement policies encouraging enterprises to invest in establishing material production bases for scaled manufacturing.

Simultaneously, rigorous quality control systems must be established to ensure consistent and stable material quality.

Enterprises should ensure reliable supply chains to support 3D printing in mechanical manufacturing.

-

Improving Relevant Standards and Certification Systems

Accelerating the development of quality standards and certification specifications for 3D printing technology is an urgent priority.

Authorities should develop 3D printing standards for processes, materials, quality, and mechanical manufacturing with expert and industry input.

Strengthening the promotion and implementation of these standards is crucial for 3D printing quality and reliability.

This can be done through workshops and seminars to raise enterprise and practitioner awareness of the standards.

Set oversight and certification to ensure standards and boost 3D printing competitiveness in manufacturing.

-

Cultivating a Professional Workforce

Universities and vocational colleges should tailor programs to market demand, offering courses in 3D printing, materials, and mechanical design.

Strengthen faculty by recruiting and training instructors with practical experience and strong teaching skills.

Enterprises should train employees in 3D printing and certifications to boost skills and industry competitiveness.

Conclusion

3D printing boosts innovation, efficiency, and design freedom in manufacturing but faces technical, material, standard, and talent challenges.

R&D, collaboration, standards, and talent development will drive 3D printing adoption and sustainable manufacturing.