Knurling on a lathe is a fascinating process. It’s a plastic deformation method where a knurling tool presses a specific pattern onto a workpiece’s surface. Unlike cutting, it doesn’t create chips. Instead, the knurling wheel applies pressure, causing the material to flow and form raised and recessed patterns. This technique boosts friction for a better grip and adds a decorative touch.

Knurling Patterns and Specifications

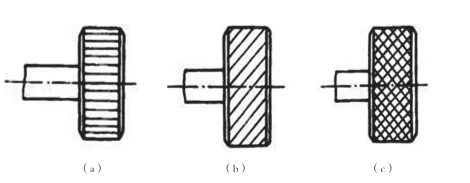

Knurling patterns primarily include straight, twill, and reticulated (like diamond and square). Our national standard, GB6403.3-86, uses a module system for knurling patterns. It defines four common types: 0.2, 0.3, 0.4, and 0.5. These correspond to tooth pitches (P values) of 0.628 mm, 0.942 mm, 1.257 mm, and 0.571 mm, respectively. Knurling also follows both metric and imperial systems. Metric P values increase by 0.1 mm (from 0.3 mm to 1.6 mm). The imperial system calculates patterns by teeth per inch.

Knurling Wheels and Tools

Knurling wheels come in various specifications. We primarily differentiate them by diameter, width, and pattern. In China, common diameters are Φ15, Φ20, Φ25, and Φ30 mm. Widths typically include 6, 8, 10, 12, 15, and 20 mm. Patterns include straight and twill. Combining two opposing twill wheels creates a net pattern.

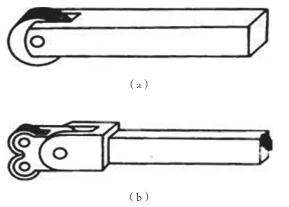

Knurling tools use a tool holder fitted with a knurling wheel. Often, we buy imported knurling wheels and then make the tool ourselves. There are three main types:

Single-wheel: This type has one knurling wheel on the handle.

Compound-wheel: This type features two opposing twill wheels. We mount these vertically on the handle, forming a pair.

Six-wheel: This tool has three sets of compound wheels on the handle. This allows for direct switching between different pattern combinations.

Knurling Process Operation

When performing knurling on a lathe, always ensure you firmly clamp the workpiece. Install the knurling tool at an angle of 3° to 5°. Apply sufficient pressure to create a clear pattern in one go. Avoid stopping midway or running out of cutting fluid, as this can damage the pattern. For both straight and mesh patterns, carefully manage rolling parameters and tool movement timing to ensure optimal results. Crucially, avoid unnecessary stops to prevent tool marks and ensure pattern quality.

Conclusion

Lathe knurling is a plastic deformation process. It works by applying pressure with a knurling wheel. This causes the material to flow and form a textured, raised, and recessed design on the workpiece surface. This method effectively increases surface friction for a better grip and adds an aesthetic touch. To ensure high-quality and efficient knurling, you must select the right knurling tool type (single-wheel, compound-wheel, or six-wheel). You also need to precisely adjust the tool’s position relative to the workpiece and control the feed speed and cutting depth.