With the deepening advancement of “smart agriculture,” agricultural machinery equipment is rapidly evolving toward high efficiency, high precision, and intelligent capabilities.

Against this backdrop, traditional mechanical design and manufacturing methods can no longer meet modern agriculture’s dual demands for equipment performance and stability.

Particularly during the machining of critical components, the absence of effective process quality control can easily lead to issues such as reduced product accuracy and insufficient reliability, thereby impacting the overall operational effectiveness of the machinery.

As a critical device for manufacturing agricultural machinery components, CNC milling machines directly determine part precision and service life through their machining quality.

However, most machining processes currently rely on post-inspection and empirical adjustments, lacking systematic, real-time quality monitoring and feedback mechanisms.

To address this, this study proposes a quality monitoring system based on intelligent sensing and data analysis. This system enables real-time quality control during CNC milling processes, thereby enhancing the intelligence level of the agricultural machinery manufacturing chain.

Analysis of Agricultural Machinery Design Methods and Manufacturing Processes

Structural Design Logic for Agricultural Machinery

The structural design of agricultural machinery must comprehensively consider the complexity of operating environments, variability of loads, and ease of maintenance.

During the design phase, functional requirement models must be constructed based on agronomic parameters such as crop types, operational loads, and soil conditions to guide system design.

Modular design and parametric modeling methods are typically employed. Three-dimensional models are built using CAD/CAE software, followed by multiphysics simulation analysis to optimize structural parameters, significantly improving design efficiency and structural rationality.

Taking the blade shaft design of a rotary tillage machine as an example, its power transmission structure must simultaneously meet torque output and impact resistance requirements. Preliminary selection is typically performed using the following fundamental dynamic equation:

Where: M is torque (N·m); P is transmission power (kW); r is blade shaft radius (m); ω is angular velocity (rad/s).

By establishing a power model through this formula, the structural load-bearing capacity can be optimized.

During the design process, finite element analysis results must be further integrated to optimize stress concentration zones within the structure. Topology optimization methods are then employed to reduce redundant material distribution, achieving the dual objectives of “lightweighting + high strength.”

Additionally, fatigue life assessment and dynamic response analysis are critical components of modern design workflows. This is particularly true for high-speed agricultural equipment such as combine harvesters and sprayers, where structural vibration control and fatigue resistance directly impact operational safety and service life.

Key Manufacturing Process Flows

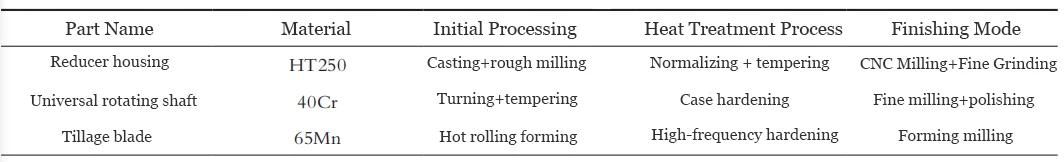

Agricultural machinery components exhibit significant diversity in type and structural complexity, necessitating tailored process flow design.

Typical examples include housing-type, shaft-type, and cutting-tool components, whose manufacturing involves multiple stages: blank forming, heat treatment, machining, and surface strengthening.

Heat treatment serves as the core method for enhancing material mechanical properties, directly impacting subsequent finishing quality and overall equipment durability.

For example, transmission shaft components often utilize 40Cr steel, which undergoes quenching and tempering to enhance yield strength, supplemented by surface high-frequency quenching to improve wear resistance.

In the machining stage, CNC milling dominates the finishing of critical components.

CNC milling machines offer high precision, rigidity, and automation, making them suitable for complex geometries and tight tolerance requirements.

To boost productivity, modern manufacturing processes widely employ integrated flexible machining cells (FMG) and machining centers (MG) to achieve centralized multi-process machining and automated batch production.

The processing flow for key agricultural machinery components is shown in Table 1.

The rationality of the process path directly determines part machining accuracy and batch consistency.

Within flexible production systems, pre-analysis of machining paths, fixture interference, and thermal deformation using process simulation software is a critical means of ensuring manufacturing quality.

Furthermore, to support the deployment of subsequent quality monitoring systems, process data collected during machining (such as spindle load, tool life, and machining temperature rise) must be stored in a standardized format. This serves as the foundational support for quality traceability and intelligent control.

Sources of Error and Monitoring Challenges in CNC Milling Processes

Analysis of Error Types and Causes

In CNC milling of agricultural machinery components, dimensional accuracy and surface quality serve as core indicators for evaluating machining quality. Fluctuations in these metrics primarily stem from the accumulation of multiple machining errors.

Based on error characteristics, common machining errors can be categorized into three major types: systematic errors, random errors, and thermal errors.

Combining a multi-factor error propagation model, dimensional deviations can be described by the following formula:

Where: L is the target machining dimension; xi represents the i-th influencing factor; Δxi is the error component; aL/axi is the sensitivity coefficient.

This model provides a mathematical basis for error source analysis.

Analysis of Monitoring Challenges

Despite the high positioning accuracy and repeatability of modern CNC machine tools, machining quality remains susceptible to dual influences from external disturbances and internal fluctuations.

In practical applications, real-time monitoring of machining quality faces numerous challenges.

First, signal coupling exhibits high complexity. During machining, the vibration spectra of the spindle, tool feed force, and cutting noise often overlap significantly, making it difficult for conventional sensors to accurately distinguish the signal characteristics corresponding to each physical quantity.

Second, sensor placement is constrained. The machining of agricultural machinery components often involves large-sized or irregular structures. Sensors must be embedded at critical locations without interfering with the machining path, imposing higher demands on equipment modification and signal stability.

Additionally, the absence of real-time decision feedback mechanisms further complicates monitoring.

Traditional inspection methods primarily rely on post-processing sampling, failing to provide immediate responses to sudden anomalies during machining. This often leads to increased defect rates or exacerbated equipment damage.

Therefore, developing an intelligent monitoring system capable of multi-source signal fusion, online identification, and feedback control represents the key pathway to resolving these issues and enhancing quality control during the machining process.

Research on Intelligent Monitoring Technology for CNC Milling Quality

Monitoring System Architecture Design

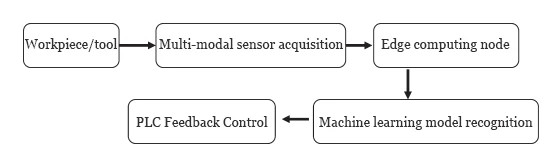

To achieve real-time quality control during CNC milling, an intelligent monitoring system based on multi-sensor fusion and edge computing architecture was developed, as shown in Figure 1.

Centered on machining state perception, this system integrates data acquisition, feature analysis, and feedback control. It employs intelligent algorithms for real-time early warning of machining quality fluctuations and parameter correction.

The system is divided into four layers: perception layer, data acquisition layer, analysis and decision layer, and feedback control layer.

The perception layer deploys multiple sensors, including high-sensitivity accelerometers (monitoring machine tool vibration), force sensors (monitoring spindle cutting force), and thermocouple arrays (monitoring tool and workpiece temperature rise).

The data acquisition layer employs a high-speed multi-channel DAQ system for synchronous sampling. Preliminary feature extraction—such as spindle power spectral density and cutting force RMS values—is performed via edge computing nodes.

The analysis and decision layer utilizes algorithms like Support Vector Machines (SVM) and Convolutional Neural Networks (CNN) for anomaly identification and classification. Based on model outputs, it drives the feedback control layer to adjust critical machining parameters such as feed rate and spindle speed, achieving closed-loop process control.

This architecture not only enhances the monitoring system’s response speed and interference resistance but also offers excellent scalability and industrial compatibility.

Intelligent Algorithms and Application Practice

To validate the monitoring system’s effectiveness, key signal data was collected during multiple machining states using spline shaft milling as the test subject.

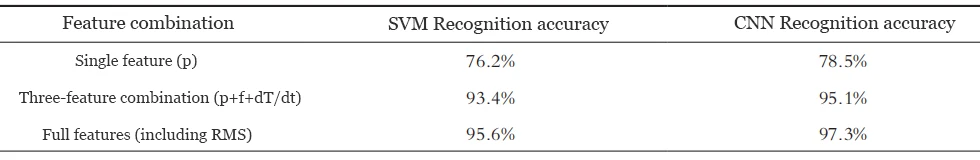

The experiment selected four feature types as input variables: spindle power (P), peak vibration frequency (f_peak), tool temperature rise rate (dT/dt), and acceleration RMS value (RMS_acc). SVM and CNN classification models were constructed for performance comparison.

During modeling, cross-validation and regularization methods were employed to enhance model robustness. The training-to-test ratio was set at 7:3 to ensure model generalization capability. Recognition results are shown in Table 2.

Experimental results demonstrate that deep learning models integrating multi-feature information exhibit higher accuracy and robustness in identifying machining anomalies, particularly showing excellent sensitivity in detecting subtle changes such as abnormal tool wear and unstable cutting.

Conclusion

Agricultural machinery manufacturing is progressively advancing toward intelligent and high-precision development stages.

This paper systematically explores intelligent monitoring techniques for CNC milling quality from structural design to manufacturing processes, validating the effectiveness of multi-sensor fusion and algorithmic recognition in practical machining.

Future research should further deepen the industrial application of data-driven models, advancing the digitalization and adaptive control capabilities across the entire agricultural equipment manufacturing process.