As a vital tool in modern transportation, the quality of aircraft fixture components directly influences aircraft performance and service life.

Machining processes are the key technology in manufacturing aircraft fixture components, exerting a decisive influence on their precision and service life.

Advancing aviation technology requires precise, reliable aircraft tooling; studying machining impacts improves performance, safety, and aerospace competitiveness.

Analysis of Aircraft Tooling Component Characteristics

Before examining specific characteristics, it is essential to understand that aircraft tooling components face unique challenges in design and manufacturing. Their structural complexity, strict precision requirements, and specialized materials collectively define the demanding standards of aerospace production.

-

Structural Complexity

Aircraft tooling, such as wings, has complex structures that must endure flight forces and meet aerodynamic demands, requiring high precision.

-

High Precision Requirements

Aircraft tooling components demand exceptional dimensional accuracy, typically operating within micrometer or even nanometer tolerances.

Wing skin thickness ±0.1mm and hole positions ±0.3mm ensure precise fits, minimize errors, and boost performance.

-

Specialized Materials

Aircraft tooling uses lightweight, strong materials, but titanium is hard to machine due to heat and tool wear.

Impact of Machining Processes on Aircraft Fixture Component Precision

Understanding the critical role of machining in aerospace manufacturing, it is important to examine how specific cutting processes influence the precision and quality of aircraft fixture components.

-

Influence of Cutting Processes

Tool selection and wear significantly affect the precision of aircraft fixture components.

Carbide tools provide high efficiency and accuracy for aluminum alloys, while ceramic tools excel with titanium alloys.

Tool wear increases cutting forces, dimensional errors, and surface roughness.

Cutting parameters like speed, feed, and depth impact accuracy; high speeds accelerate tool wear, heat, and deformation.

while excessive feed rates increase surface roughness and reduce dimensional accuracy.

Only by optimizing cutting parameters can machining efficiency be maintained while improving precision.

-

Impact of Specialized Machining Processes

EDM uses electrical discharge erosion to machine complex molds and components.

EDM machines deep holes and narrow slots in aircraft tooling that conventional methods cannot reach.

Since no cutting forces are present during EDM, deformation of the workpiece due to stress is avoided, thereby ensuring machining accuracy.

Laser processing provides high-precision, high-speed, non-contact machining, enabling shaping and micro-hole drilling in aircraft tooling.

Laser precision depends on beam energy, spot size, and parameters; optimizing these ensures high-accuracy machining.

-

Impact of Assembly Processes

Proper positioning and clamping ensure accuracy in aircraft tooling assembly; the one-face-two-pin method constrains all six degrees of freedom.

Incorrect clamping affects accuracy: over-tightening deforms parts, under-tightening allows displacement.

Machining and assembly errors require adjustments to ensure assembly accuracy.

During assembly, shims, adjustment bolts, and similar tools can be used to adjust component positioning and clearances, compensating for machining errors.

Impact of Machining Processes on Aircraft Fixture Component Lifespan

Beyond dimensional precision, the longevity of aircraft fixture components is heavily influenced by surface quality and residual stresses, which play a critical role in determining fatigue life under operational loads.

-

Influence of Surface Quality on Fatigue Life

Higher surface roughness increases stress concentration, promoting fatigue cracks and reducing aircraft fixture component life.

Smoother surfaces on aircraft landing gear components can boost fatigue life by over 20% by reducing stress concentrations and delaying crack formation.

Furthermore, residual surface stresses are categorized as tensile or compressive. Tensile stresses reduce component fatigue life, while compressive stresses enhance it.

Cutting parameters and tool wear induce residual stresses, while shot peening and roll forming introduce compressive stresses to improve fatigue life.

Aerospace manufacturers use shot peening on engine blades to induce compressive stress and extend fatigue life.

-

Impact of Processing Defects on Life Loss

Internal defects in aircraft tooling components, primarily including porosity, inclusions, and cracks, significantly reduce component strength and fatigue life.

Improper process control during casting and forging operations often leads to internal defects.

Unreasonable forging of turbine disks can cause internal cracks, reducing service life and risking safety incidents.

Cutting and grinding can cause burns and scratches, damaging the surface microstructure and reducing fatigue life.

Process Optimization Strategies to Enhance Precision and Lifespan of Aircraft Tooling Components

To further enhance both precision and component lifespan, adopting advanced machining technologies is essential. These methods enable complex geometries to be processed more accurately and efficiently, minimizing errors and material stresses.

-

Application of Advanced Machining Technologies

5-axis simultaneous machining technology.

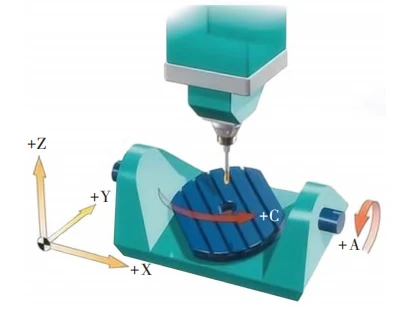

Five-axis CNC machining moves three linear (X, Y, Z) and three rotary (A, B, C) axes, allowing the tool to reach any orientation and significantly increasing flexibility (Figure 1).

In machining monolithic wing panels, traditional 3-axis machining requires multiple setups, each introducing positioning errors that can accumulate to ±0.5mm.

In contrast, 5-axis machining completes complex surface machining in a single setup with positioning accuracy of ±0.05mm, reducing cumulative errors by 90%.

Toolpaths are planned in CAD/CAM from the 3D model, with tool tilt adjusted to avoid interference on curved wing panels.

Real-time monitoring adjusts spindle speed and feed to control cutting forces and prevent workpiece deformation.

Composite Machining Technology.

Turning-milling combines turning and milling on one machine, reducing setups, minimizing errors, and improving accuracy and efficiency.

Aircraft engine casings combine rotary surfaces (cylindrical, conical) and milled features (flat surfaces, grooves).

Integrated turning-milling cuts the production cycle from 15 to 7 days and improves tolerances from ±0.3mm to ±0.1mm.

Integrated turning-milling requires planning sequences based on the casing’s structure and processing needs.

Prioritize rough turning to remove most stock, thereby reducing the load on subsequent milling operations.

Layered milling controls depth, reduces cutting forces and deformation, and optimizes toolpaths to improve efficiency.

-

Process Control and Monitoring

Online Inspection Technology.

Online inspection uses lasers and CMMs to provide real-time workpiece data for CNC closed-loop control.

In aerospace gear machining, profile accuracy affects performance and life. Traditional offline inspection led to 15% scrap, while online inspection reduced it below 3%.

A laser system on the machine table measures gear tooth profiles and directions in real time during cutting.

If dimensions deviate beyond ±0.02mm, the CNC system automatically adjusts tool compensation and the path to maintain accuracy.

Statistical software analyzes inspection data to predict tool wear, enabling timely replacement and maintaining accuracy.

Machining Process Simulation.

Machining simulation uses mechanical models to predict cutting forces, heat, and their effects on workpiece deformation and accuracy.

FEA simulation of a new titanium component showed 0.2mm deformation under standard cutting, exceeding design limits.

Optimizing cutting—30% lower speed, 20% higher feed—cut deformation to 0.08mm, meeting specifications.

Accurate workpiece, tool, and machine models, with fixed material and cutting parameters, enable simulations to predict issues such as tool breakage and chatter.

Adjust parameters, optimize toolpaths, and re-simulate until optimal. Simulation cuts trial runs from 5 to 1, shortening development and reducing costs.

Conclusion

Machining affects aircraft tooling precision and life; proper techniques and control enhance performance and durability.

Aviation manufacturers should adopt new machining techniques to optimize processes and strengthen China’s aerospace industry.