Aluminum alloys, especially thin-walled shells, meet high-performance needs and boost innovation in key industries.

With broader use and higher performance demands, machining deformation in shaped thin-walled aluminum shells increasingly limits their development.

Thin-walled aluminum shell deformation requires comprehensive control to ensure quality and support wide application.

Deformation prediction of shaped thin-walled aluminum alloy shell workpiece

Application cases

Shaped thin-walled aluminum shells are crucial in aerospace, with complex geometry demanding strict deformation control.

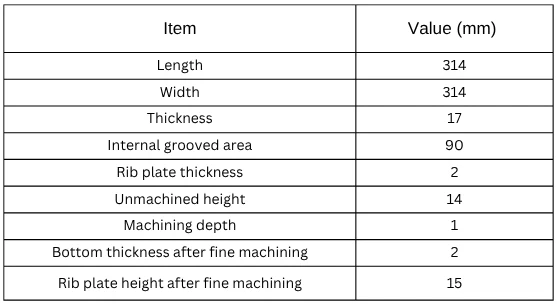

The shaped thin-walled aluminum shell (Fig. 1), made from 7050 alloy (Table 1), fulfills aerospace material standards.

Figure 1 Aerospace equipment exterior cylinder structure

Table 1 Design dimensions

Geometric modeling

The cylinder and ribbed plate groove structures make it difficult to clamp and support the workpiece.

The thin cylinder wall easily deforms during machining, affecting workpiece accuracy and performance.

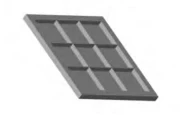

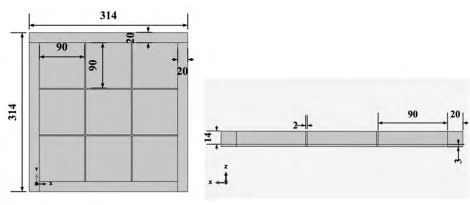

CATIA predicts deformation by modeling the workpiece (Fig. 2) and defining dimensions (Fig. 3).

Dense meshing of thin-walled cavity ribs enhances simulation accuracy while keeping simulation time low.

Fig. 2 Geometric simulation model of the workpiece

Fig. 3 Dimension of the geometric simulation model

Tool path planning

Researchers study the influence of machining paths on deformation using zigzag, inner-ring, and outer-ring paths across nine groove areas.

Users input the tool path into MATLAB to align tool coordinates with grid numbers, enabling precise grid removal.

Groove grids matrix the tool positions of three paths, ordering them from a11 to ann to simplify paths and mark loading and machining sequences.

Simulation Experiment

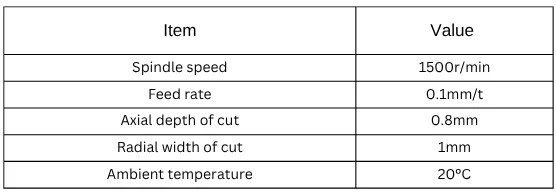

Researchers must clarify and keep experimental parameters (Table 2) constant during simulations.

Maintaining consistent cutting force excludes other influences, focusing on machining path impact for reliable conclusions.

Machining starting points influence deformation, notably in precision work, because stiffness changes dynamically during cutting.

Analysis of deformation maps shows the nine regions should be milled using the outer ring sequence.

Slot cavity machining deformations for word, inner ring, and outer ring paths are 0.0287, 0.0414, and 0.0227mm, with averages of 0.0101, 0.0119, and 0.0089mm.

To balance efficiency and deformation control, the workpiece milling should start with the outer ring path to ensure stability and reduce deformation.

Table 2 Simulation experiment parameters

Control measures for deformation of shaped thin-walled aluminum alloy shell workpiece

Optimize material selection

Selecting suitable aluminum alloy and tool materials ensures processing quality and stable performance of shaped thin-walled aluminum shell workpieces.

Choosing aluminum alloys requires assessing mechanical properties, cost-effectiveness, supply, and environmental impact to ensure processing needs and sustainability.

Cutting tools should use hard, tough materials with proper angles, like tungsten carbide, to reduce friction and improve machining accuracy.

To ensure stable tool performance, establish a wear monitoring system and regularly replace severely worn tools to maintain processing quality.

Control the processing temperature

Aluminum alloy’s unique thermophysical properties cause thermal expansion at high temperatures, reducing dimensional accuracy and risking irreversible deformation.

We must strictly control processing temperature to ensure workpiece quality and stability.

To counter aluminum alloy’s thermal expansion, spray cooling water on the machining area to remove heat and prevent thermal deformation.

Secondly, upgrade machine cooling to further stabilize machining temperature.

Install fans and cooling tubes on key machine tool parts to improve heat dissipation.

Optimize the machine tool’s lubrication system to maintain lubrication at high speeds and reduce friction heat.

Finally, the control of processing temperature also needs to be combined with specific processing technology and workpiece requirements.

Improve the machining process

Choosing machining processes and equipment affects deformation control; thus, in-depth research is needed to improve quality and efficiency.

First, optimize the structural design, reduce material waste, reduce processing difficulty, and then reduce the risk of workpiece deformation.

Thin-walled structures deform easily; mold design must consider geometry, material, and machining to ensure accurate, stable replication.

Choose methods by workpiece type; set parameters to optimize efficiency, quality, and deformation.

Improve workpiece clamping

Traditional clamps often fail to support shaped thin-walled aluminum shells, causing deformation during machining.

Therefore, it is necessary to adopt a more suitable clamping strategy for its characteristics.

Use rigid axial end-face compression to support and fix the workpiece, reducing vibration and deformation during machining.

To improve clamping stability, use special clamps or pads for uniform force distribution, preventing local stress and workpiece deformation.

Vacuum suction cups clamp complex workpieces uniformly, preventing deformation from uneven pressure.

Conclusion

In summary, shaped thin-walled aluminum shells deform easily, challenging manufacturing.

To solve this, deeply understand aluminum alloy properties and shell design, predict deformation via simulation, and develop effective control methods.

To control deformation, optimize materials, temperature, machining, and clamping to boost quality and efficiency.