In 2020, after Tesla’s Shanghai plant produced its first one-piece cast floor, Chinese automakers began exploring and testing one-piece casting.

The integrated die-casting process offers the following advantages:

A. By cutting 370 parts to just 2, integrated die-casting streamlines the body structure and greatly boosts production efficiency.

B. The aluminum alloy die-casting process enhances strength by using metal solidification and optimizing design with ribs and variable wall thickness.

reducing hundreds of connection points, significantly improving consistency, and minimizing instability in inter-process interactions.

The overall strength and mechanical performance surpass those of traditional body structures.

C. Die-cast aluminum alloy reduces floor weight by ~19% through optimized design, enhancing lightness, strength, range, and energy efficiency.

D. Die-casting offers high flexibility, shorter cycle times, and greater efficiency, making it ideal for mass production.

Replacing hundreds of parts with 1–2 die-cast components cuts welds, shortens production from hours to minutes, and boosts supply efficiency.

E. Replacing many stamped and welded parts cuts connection steps, reduces robot use, shortens lines, and saves space.

Mass production and process improvements can further optimize cost reduction.

This paper offers reference suggestions by comparing the pros and cons of each process route.

Introduction to the Integrated Die-Casting Process

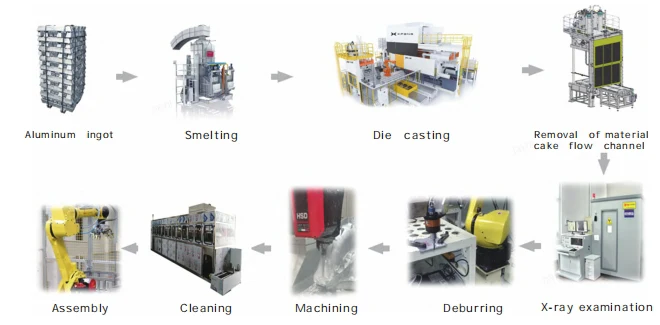

The integrated die-casting process covers melting, casting, cooling, trimming, inspection, machining, cleaning, and assembly (see Figure 1).

Figure 1 Integrated Die-Casting Process Flow

The melting process is primarily divided into two routes: self-melting and direct supply of molten aluminum.

Gate removal is divided into two routes: plasma cutting and edge trimming machine.

Deburring is divided into three routes: manual, automatic, and adaptive grinding.

Dimension control adopts two routes: random inspection and online shaping and measurement.

Machining uses two routes: cutting fluid and minimal lubrication;

Cleaning is divided into two routes: no cleaning and cleaning;

Assembly can choose from self-tapping threads, stud welding, riveting, drawn rivet nuts and studs, self-tapping screws, etc.

However, due to the differing actual conditions of each enterprise, there are variations in process routes and layout.

Companies face high off-season energy use, plasma cutting spatter, die-casting dimensional issues, and inefficient parts and processes.

These cause more equipment failures, lower efficiency, higher energy use, and unstable quality compared to traditional vehicle production.

Integrated Die Casting Process Application Research Analysis

Melting Process Application Analysis

Aluminum for integrated die casting comes from in-house melting or direct supply.

In-house melting enables flexible production but wastes energy and raises costs at low volumes.

Melting furnaces typically require periodic maintenance, with maintenance periods lasting approximately one month.

During this time, the entire die casting unit must cease production, causing production capacity losses for the automotive manufacturer.

Direct molten aluminum supply cuts downtime and costs but faces delivery limits due to hazardous transport, requiring nearby factories.

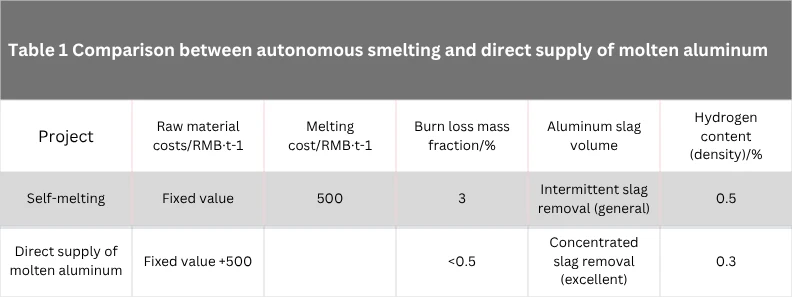

Comparing costs and quality, direct aluminum supply is about 400 yuan/t cheaper than in-house melting (see Table 1).

Direct supply cuts costs, prevents downtime from equipment issues, and ensures higher quality through centralized refining compared to in-house melting.

Application Analysis of Dimension Control

Large one-piece die-cast floor panels often show dimensional fluctuations, causing bonding and fit issues.

Inadequate dimension control can cause significant challenges for subsequent processes.

The current main process routes include offline gauges, blue light or laser radar spot checks, and online 100% measurement at critical points.

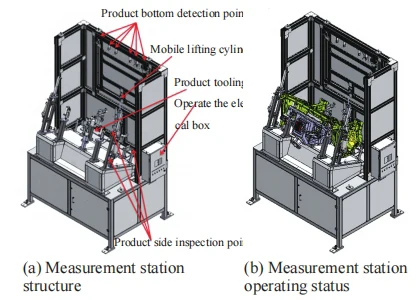

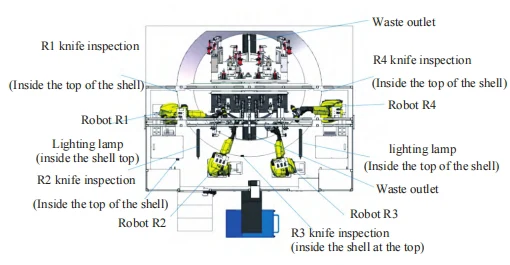

Figure 2 shows a photoelectric station for fast, precise multi-point measurement and analysis.

However, post-production measurement is merely a detection method and does not fundamentally resolve dimensional variation issues.

Some companies use forming dies for 100% post-line part forming to improve dimensional consistency.

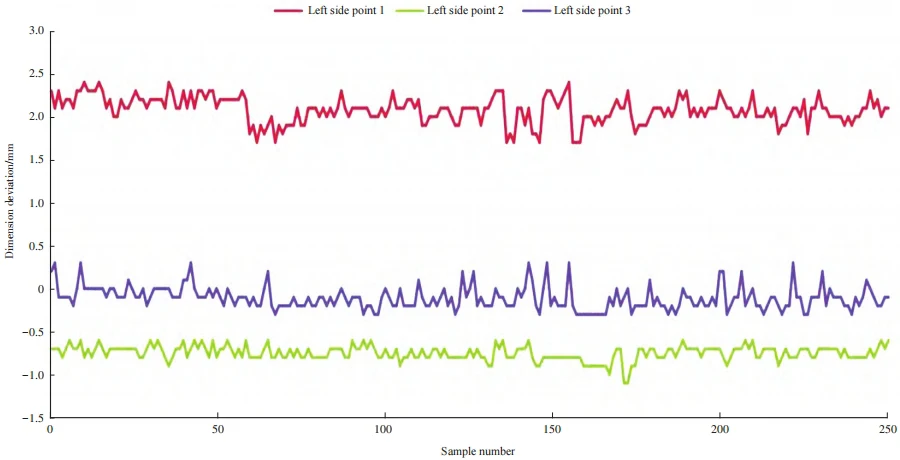

Figure 3 shows A-pillar measurements after forming in the front compartment.

Forming dies adjust quantities by mold conditions and, with measurement monitoring, ensure effective dimensional control.

Deburring Process Application Analysis

Flash and burrs on die-cast parts cause quality and safety issues, making their removal essential in the process.

Manual grinding is common due to low cost but has low efficiency, poor conditions, and incomplete burr removal.

Some companies use robot milling for deburring but face over-cutting or incomplete removal due to dimension variations.

Adaptive grinding is needed: parts are measured before grinding, deviations are calculated, and suitable programs are selected to ensure quality.

Cleaning Process Application Analysis

OEMs like Tesla, Xiaomi, and Zeekr use CNC minimal lubrication without cleaning to reduce costs and energy.

Assembly Process Application Analysis

One-piece die-cast floors use various assembly methods like stud welding, riveting, and self-tapping screws.

Currently, most companies use manual riveting processes for assembly operations to ensure higher flexibility and efficiency;

Some companies use automatic riveting, but tight tolerances and mixed CNC parts cause jams and short tool life, lowering machine use.

Stud welding avoids hole machining, cuts equipment costs, and is cheaper per weld than riveted studs.

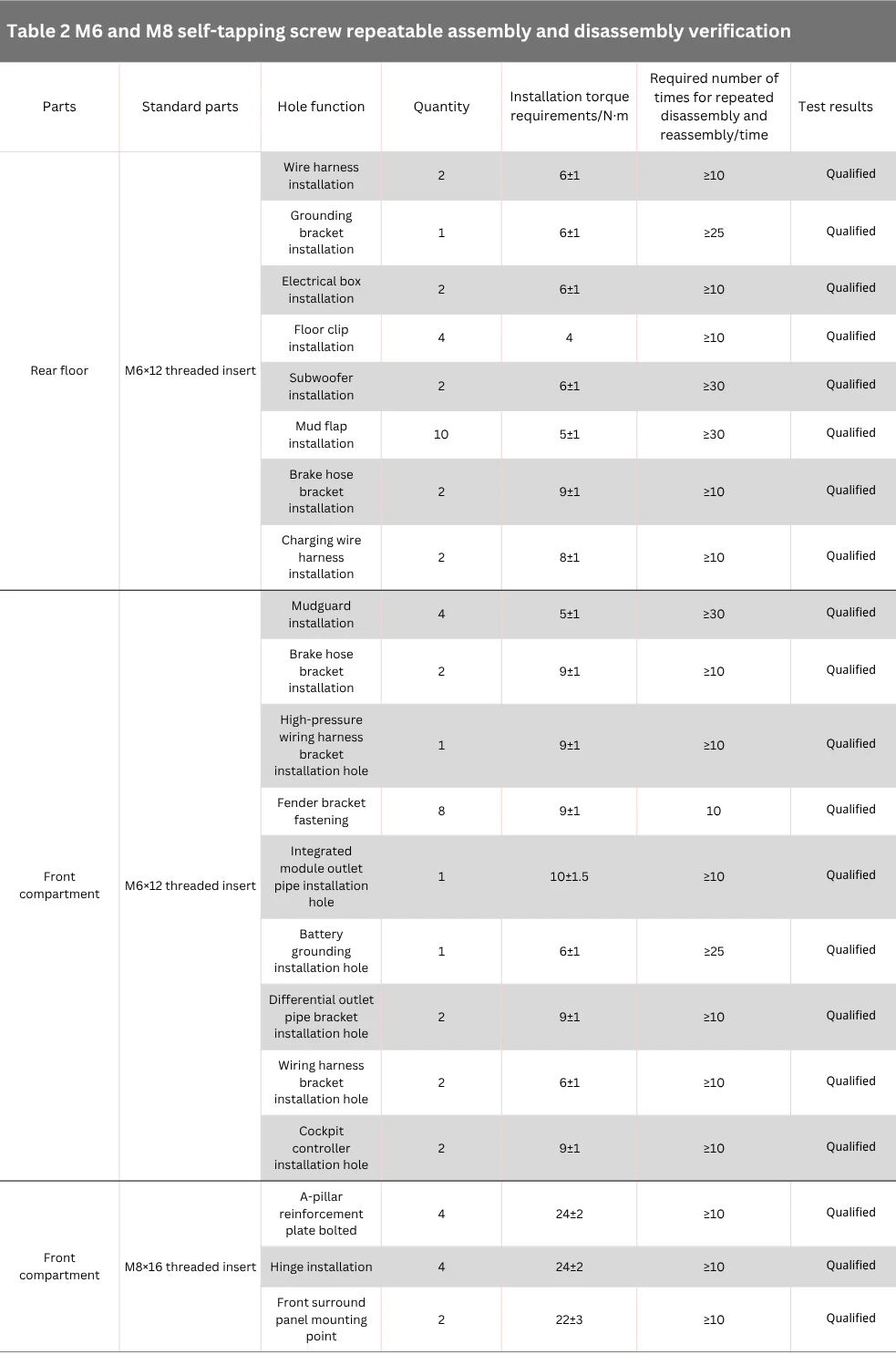

Using thread tapping instead of inserts cuts CNC time and parts. Table 2 and Figure 5 show M6 and M8 tapping results for a vehicle model.

The M6 body threading process fully meets the requirements of the thread insert process.

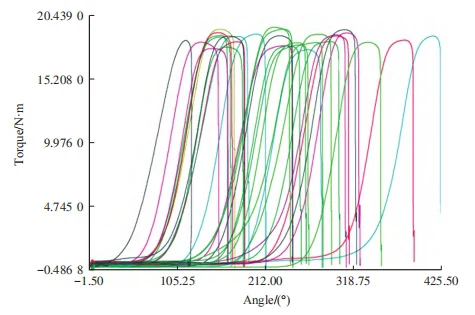

Figure 5 M6 self-tapping thread repeatable assembly/disassembly 30 times Atlas tightening gun tightening torque curve

Tail-less thread inserts save installation time and tools versus tailed inserts, boosting efficiency.

Conclusion

This paper conducted research and analysis on different process routes for critical processes in die-casting technology. Under current technical conditions:

When feasible, direct aluminum liquid supply cuts costs and avoids furnace maintenance downtime.

Using forming dies for shaping and online 100% critical point dimension measurement processes can ensure dimensional stability;

Implementing adaptive grinding and deburring processes through a joint measurement station can improve grinding efficiency and deburring quality;

Using stud welding, self-tapping threads, tail-less inserts, and manual riveting boosts efficiency and cuts costs.