Micrometers are essential precision measuring instruments widely used in mechanical engineering, manufacturing, and quality control to achieve highly accurate dimensional measurements.

This article provides a comprehensive overview of standard mechanical and digital outside micrometers, including their structure, measurement principles, and reading methods.

It also covers critical components such as the measuring force device, and offers detailed guidance on proper usage, precautions, and maintenance to ensure accuracy, extend lifespan, and optimize performance in practical applications.

Standard Mechanical Outside Micrometer

The names of each part and the main components are shown in the figure below:

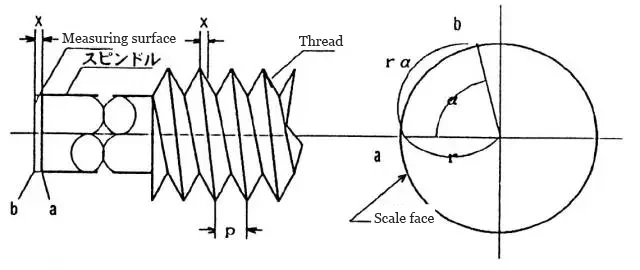

Measurement Principle of the Standard Mechanical Micrometer

The spindle moves 0.5 mm per revolution, divided into 50 micrometer scale divisions, giving 0.01 mm per division.

Measurement principle diagram of a standard mechanical micrometer

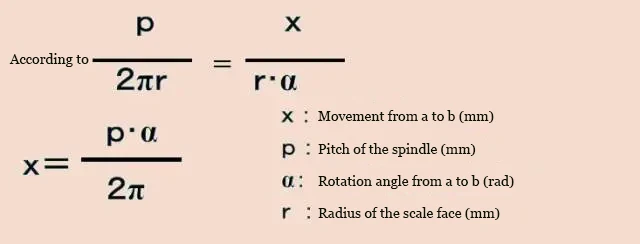

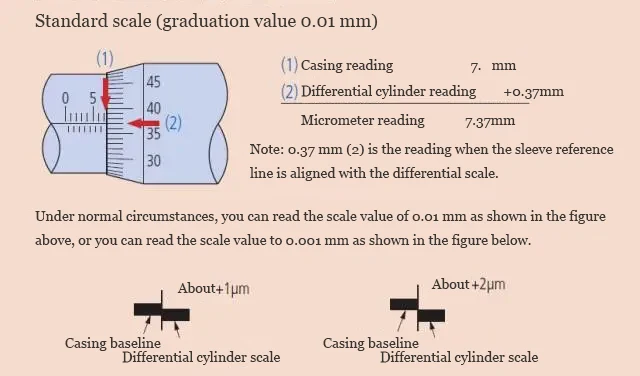

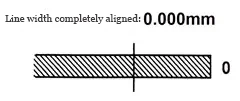

Reading the scale of a standard mechanical micrometer

After aligning the baseline, we can determine the last digit of the dimension based on the position of the baseline.

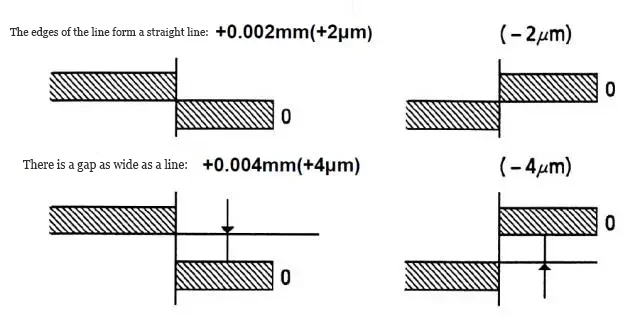

Digital Outside Micrometer

The basic structure is shown in the figure below.

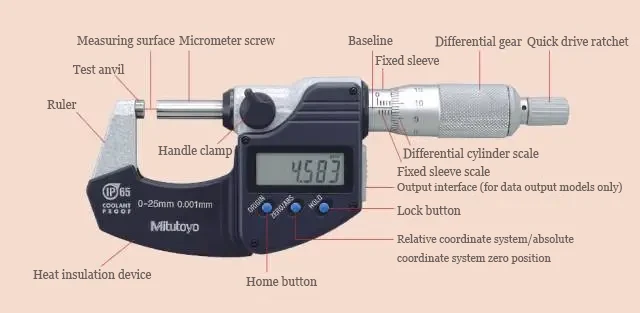

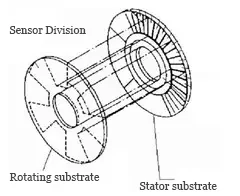

Measurement Principle of a Digital Outside Micrometer

The resolution is 0.001 mm. The distance traveled by the spindle in one revolution is 0.5 mm, which is divided into 500 divisions by the sensor (rotor, stator). 0.5 mm ÷ 500 = 0.001 mm.

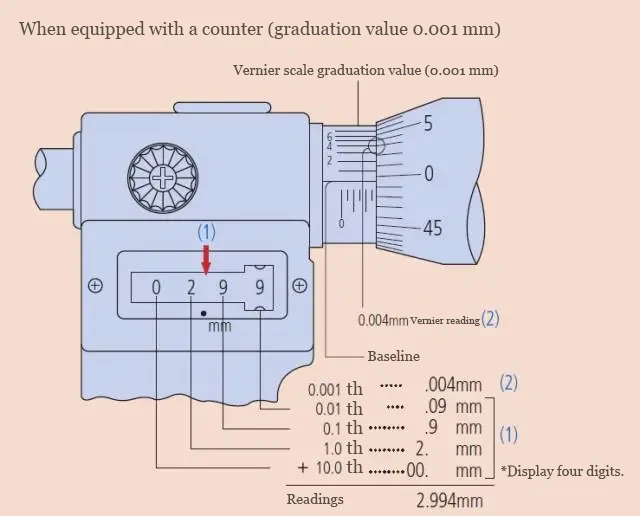

In addition to the two common types of micrometers mentioned above, there is also this type of outside micrometer with a counter.

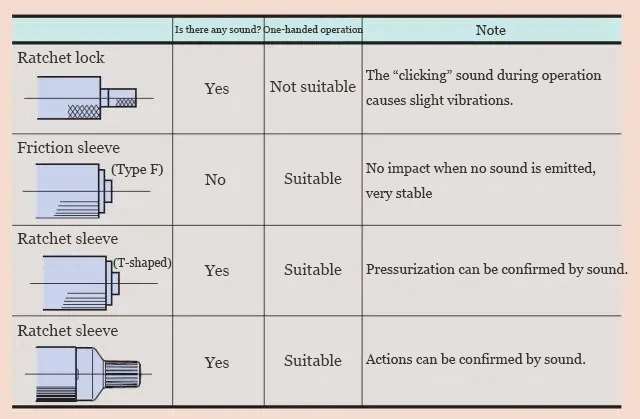

Micrometer force measuring device

The measuring force device of a micrometer is also a very important component.

Proper use can extend the lifespan of the micrometer and improve measurement accuracy.

Note: This chart is from the Mitutoyo Micrometer Force Measurement Device Overview.

Precautions for Using Micrometers

After covering micrometer structure and reading, focus on usage precautions and maintenance.

- Carefully check the type, measurement range, accuracy, and other specifications to select the appropriate model for your application.

- Before measuring, let the micrometer and workpiece reach room temperature so their temperatures are balanced.

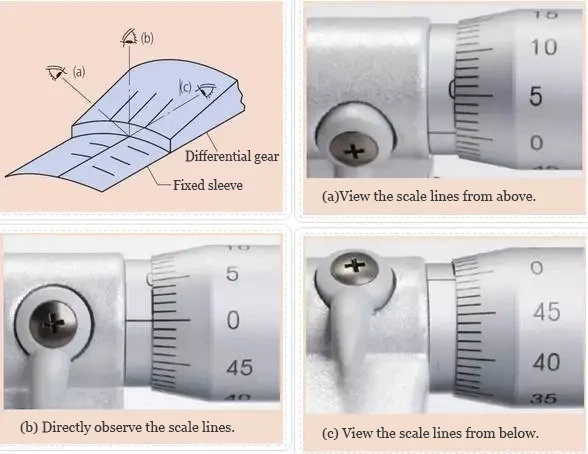

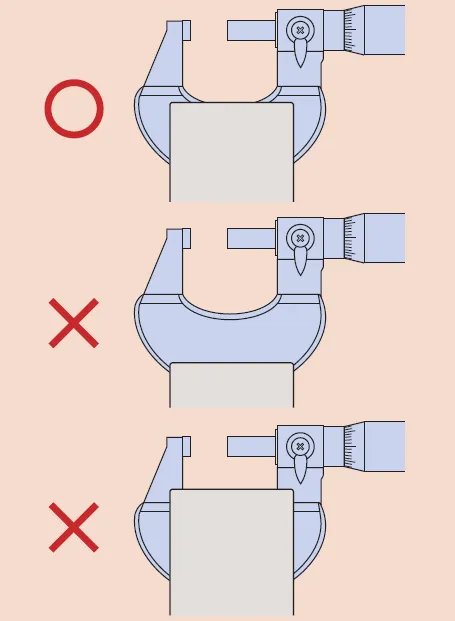

- When reading the scale lines on the micrometer, look directly at the reference line.

If you view the scale lines from an angle, visual errors will prevent you from reading the correct position of the lines.

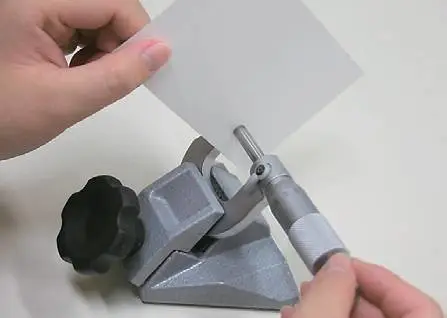

- Adjust the starting point (zero) before measurement. Use lint-free paper to wipe the measuring surfaces of the measuring anvil and micrometer screw.

- For routine maintenance, clean dust and debris from the environment and measuring surfaces, and wipe stains or fingerprints with a dry cloth.

- Use the force measurement device correctly to apply the correct measuring force.

- When installing the micrometer onto the stand, clamp the stand securely at the center of the micrometer frame. However, do not clamp it too tightly.

- Ensure the micrometer does not fall or collide with any objects. Do not apply excessive force when rotating the micrometer’s micrometer screw.

If you suspect accidental misuse has damaged the micrometer, inspect its accuracy before using it.

- After prolonged storage or if a protective oil film is present, gently wipe the micrometer with a cloth soaked in corrosion-resistant oil.

- Storage precautions: Avoid direct sunlight when storing. Store in a well-ventilated, low-humidity location.

Store in a dust-free location. If you store the micrometer in a box or other container, keep the container off the ground.

During storage, leave a gap of 0.1mm to 1mm between the measuring surfaces. Do not store the micrometer in a clamped state.

Maintenance and care of micrometers during use

First: Carefully wipe off any dirt or fingerprints from all parts using a dry cloth.

For long-term or dry storage, coat the micrometer with a thin layer of anti-rust oil to preserve performance, even if it leaves slight stains.

Finally, when storing the micrometer, please note the following points.

- Store in a location away from direct sunlight, with low humidity, good ventilation, and minimal dust.

- Always store in a storage case; do not place directly on the ground.

- Store with measuring surfaces slightly open (0.1–1 mm) and avoid locking to prevent malfunctions.

Conclusion

In conclusion, micrometers—whether standard mechanical or digital—remain indispensable tools for achieving precise measurements in mechanical engineering and manufacturing.

Understanding their structure, measurement principles, and proper reading techniques is essential for accuracy.

Equally important are correct usage practices, regular maintenance, and careful storage, which ensure reliable performance, extend the lifespan of the instrument, and prevent costly measurement errors.

By following these guidelines, engineers and technicians can maximize the effectiveness of micrometers and maintain the high standards required in precision measurement applications.