Industry 4.0 leverages the Internet, IoT, big data, and AI to enable intelligent, digital, and flexible production.

Amid Industry 4.0, automated mechanical production lines evolve into intelligent systems, integrating equipment with information systems to boost flexibility and responsiveness.

However, the intelligent upgrade of automated production lines faces numerous challenges.

Integration of traditional automation with intelligent tech remains limited, as weak data transmission and processing hinder smart production line transformation.

Intelligent upgrades require deep integration of technology, equipment, and management, with hurdles in innovation and investment.

Thus, advancing intelligent upgrades of automated lines under Industry 4.0 has become an urgent challenge for manufacturing.

Upgrade Requirements for Automated Production Lines in Mechanical Manufacturing under Industrial 4.0

To meet the challenges of Industry 4.0, mechanical manufacturing enterprises must transform their traditional automated production lines into intelligent, flexible systems.

This transformation involves not only upgrading equipment and integrating advanced technologies but also addressing operational inefficiencies that limit production capacity.

The following section explores the primary driver behind such upgrades: the need to enhance production efficiency.

Demand for Enhanced Production Efficiency

The need to boost production efficiency serves as the core driver for the intelligent upgrade of automated production lines in mechanical manufacturing.

Amid intensifying market competition, manufacturing enterprises must accomplish more production tasks within the same timeframe.

Traditional automated production lines, however, face significant bottlenecks in production:

First, equipment utilization is low, as preset process flows hinder real-time optimization, leaving some machines inefficient or idle.

Second, outdated scheduling and poor data flow hinder coordination on automated lines, creating bottlenecks and limiting capacity.

Thus, upgraded lines need efficient data flow, intelligent scheduling, and adaptive optimization to cut idle time and boost output.

Production Quality Optimization Requirements

Production quality directly impacts a company’s market competitiveness and cost control capabilities.

Traditional manufacturing models primarily rely on manual expertise and post-production inspection for quality control, presenting two main issues.

Without real-time monitoring, inspectors miss quality issues, letting defects spread and raising rework costs.

Second, temperature, humidity, and vibration affect machining precision, and without compensation, manufacturers struggle to ensure consistency.

Manufacturers must equip upgraded lines with real-time monitoring to reduce scrap, improve consistency, and enable traceable data.

Design of Intelligent Upgrade Solutions for Automated Production Lines

To implement intelligent upgrades effectively, automated production lines must incorporate advanced monitoring and control technologies.

Among these, smart sensors play a crucial role by providing accurate, real-time data on material movement, equipment status, and environmental conditions.

The following section details how smart sensors are integrated into production lines to enable precise monitoring, dynamic optimization, and seamless connectivity with management systems.

Smart Sensor Integration

Under Industry 4.0, smart sensors at key nodes provide real-time, precise monitoring and data collection across production lines.

Engineers select adaptable smart sensors based on specific monitoring requirements.

Engineers employ the Omron E3Z-D61 photoelectric sensor for material position and displacement monitoring.

With a detection range of 500 mm and a response time of just 0.01 seconds, it precisely captures minute material movements.

Engineers monitor equipment vibration using the Keyence KD2-E02 accelerometer (±16g, 0.5–10,000 Hz) to detect abnormal operational vibrations.

Temperature monitoring utilizes the Siemens QAA2301 temperature sensor.

It monitors critical equipment temperatures from –50 to 150°C with ±0.5°C accuracy, alerting promptly to overheating.

Engineers scientifically plan the installation locations and quantities of smart sensors based on the automated production line’s process flow and equipment layout.

Photoelectric sensors placed every 2 meters on the conveyor monitor material presence, position, and speed for precise distribution.

Vibration and temperature sensors at key spindle and tool magazine points capture comprehensive equipment status data.

Engineers space vibration sensors ≤30 cm and temperature sensors ≤50 cm to dynamically monitor machining, detecting tool wear and thermal deformation.

Smart sensors use industrial Ethernet, Profibus, Modbus, TCP/IP, and other protocols to seamlessly connect with control, SCADA, and management systems.

Sensor data integrates with MES and ERP to streamline production, enhance collaboration, and drive intelligent manufacturing.

Introduction of TSN Technology

Under Industry 4.0, intelligent upgrades of automated lines demand higher network speed, reliability, and bandwidth.

The H3C IE4320-28TSN-L switch, supporting TSN, ensures connectivity for diverse production line equipment.

Use the web interface to configure ports with IEEE 802.1Qbv, assigning time slots for high- and low-priority data.

The high-priority time slot width is set to 100 μs with a 1 ms cycle; the low-priority time slot width is set to 200 μs with a 1 ms cycle.

Control signals like robot and PLC data are assigned high-priority slots, while equipment status and periodic production data use low-priority slots.

Wireshark shows high-priority data <1 ms delay; adjusting its 120 μs slot ensures timely transmission and improves automation efficiency.

Self-Learning Quality Management

Engineers use an algorithm combining SVM and DNN to ensure consistent product quality.

Specifically, SVM classifies initial data to accurately delineate different quality categories.

DNN extracts higher-level features and makes predictions to improve the model’s precision and adaptability.

Data modeling is done with Python and TensorFlow.

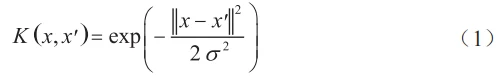

SVM classifies input features using a radial basis function kernel:

Where: K(x, x’) denotes the kernel function; x and x’ represent input data points; σ is the kernel width, serving as a measure of similarity between data points.

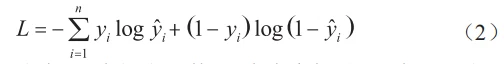

During DNN training, the cross-entropy loss measures the difference between predictions and true labels:

Where: L denotes the loss function; yi represents the true label; ŷi

indicates the predicted value; n signifies the number of samples.

This loss function minimizes error through the backpropagation algorithm, thereby optimizing model parameters.

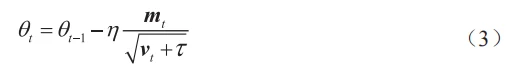

During training, the Adam optimizer dynamically adjusts the learning rate, expressed as

Where: θt is the parameter at iteration t; η is the learning rate; mt and vt are the first-order and second-order moment estimates of the gradient, respectively;

τ is a small constant added to prevent the denominator from becoming zero. Consequently, the Adam optimizer effectively accelerates convergence and enhances the accuracy of quality prediction under varying production conditions.

VR-3000 series image measuring instruments, with ±0.5 μm accuracy, are used for quality control.

They enable rapid detection of critical quality parameters such as product dimensions and shape.

When quality deviations exceed thresholds, the system triggers alerts and adjusts parameters via the self-learning model.

Industrial IoT connects equipment for real-time data sharing and self-learning quality management, improving efficiency and product quality.

Comparative Experiment

To assess the impact of the intelligent upgrade on production performance, a structured comparative experiment was designed.

This experiment aims to evaluate differences in efficiency, precision, and process adaptability between traditional automated production lines and lines enhanced with the proposed intelligent system.

The following section describes the experimental setup, including the configuration of control and experimental groups.

Experimental Preparation

To validate the effectiveness of the proposed intelligent upgrade solution, a comparative experimental platform was established.

The control group used a traditional automated production line with conventional equipment, manual data sampling, and no real-time device coordination.

The experimental group used the intelligent upgrade solution, with both groups producing 500 components daily under standardized conditions.

The experimental group used the intelligent system to dynamically optimize cutting speed (100–300 m/min) and feed rate (0.1–0.5 mm/rev).

The control group operated with fixed parameters: a cutting speed of 200 m·min⁻¹ and a feed rate of 0.3 mm·r⁻¹.

Experimental Results

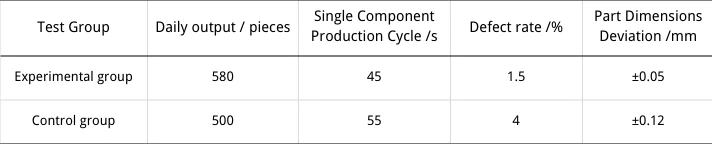

Comparative experiments measured average daily output, production cycle, defect rate, and component dimensional deviations for both groups (see Table 1).

With intelligent scheduling, the experimental group produced 580 pieces daily—a 16% increase over the control group’s 500.

Regarding production cycle time, the experimental group averaged 45 seconds per part, significantly faster than the control group’s 55 seconds.

For production quality, the experimental group achieved a defect rate of only 1.5% through real-time quality monitoring and feedback control.

In contrast, the control group’s defect rate reached 4.0% due to the absence of real-time monitoring.

Regarding dimensional accuracy, the experimental group maintained part size deviations within ±0.05 mm, meeting high-precision product standards;

the control group’s deviations reached ±0.12 mm, necessitating rework for some products.

In summary, the intelligent upgrade clearly improved production efficiency and quality, meeting Industry 4.0 standards for automated manufacturing.

Conclusion

Intelligent upgrades of production lines drive industrial development and societal progress while reflecting technological advancement.

Under Industry 4.0, intelligent production lines will be key to boosting manufacturing competitiveness.

Machinery manufacturers should adopt advanced technologies, innovate production, and stay competitive.