Machining internal holes presents far greater challenges than external cylindrical surfaces, requiring precise control over tool rigidity, heat dissipation, and chip removal.

Unlike turning, where the cutting zone is exposed, hole machining forces the tool to operate within confined spaces, making deformation, vibration, and thermal distortion major concerns.

From initial drilling and reaming to advanced processes like boring, diamond boring, and honing, each method balances efficiency, accuracy, and surface quality to meet the stringent demands of modern production.

In this article, we explore the principles, tools, techniques, and applications of hole machining, providing a comprehensive guide for achieving precision and consistency in internal cylindrical features.

Operators face tougher conditions when boring, making hole machining more difficult than external turning.

Hole diameter limits boring tool size, causing poor rigidity, bending, and vibration.

When using fixed-size tools for hole machining, the hole dimensions often directly depend on the corresponding tool dimensions.

Manufacturing errors and wear in the tool directly affect the machining accuracy of the hole;

During hole machining, the cutting zone is located inside the workpiece, resulting in poor chip evacuation and heat dissipation conditions.

This makes it difficult to control both machining accuracy and surface quality.

Drilling and Reaming

Drilling

Drilling is the initial process for creating holes in solid materials, typically with diameters under 80mm.

Drilling employs two methods: either the drill rotates or the workpiece rotates.

Drill-rotation drilling errors differ: asymmetric edges or low rigidity can skew the hole centerline, while diameter remains mostly unchanged.

Conversely, in workpiece-rotation drilling, drill deviation causes diameter variation while the hole centerline remains straight.

Common drilling tools include twist, center, and deep-hole drills, with twist drills most widely used (diameters 𝞥0.1–𝞥80 mm).

Low stiffness and poor centering cause drill bits to achieve only IT13–IT11 precision.

Surface roughness is also relatively high, typically Ra 50–12.5 μm. However, drilling offers high metal removal rates and cutting efficiency.

Drilling is primarily used for holes with lower quality requirements, such as bolt holes, thread pilot holes, and oil holes.

For holes requiring higher machining accuracy and surface quality, subsequent processes such as reaming, boring, or grinding should be employed.

Reaming

Reaming involves further processing of pre-drilled, cast, or forged holes using reamers to enlarge the diameter and improve hole quality.

Reaming can serve as a pre-finishing step before precision holes or as the final finish for holes with less stringent requirements.

Reamers resemble twist drills but feature more cutting edges and lack a cross-edge.

Compared to drilling, reaming exhibits the following characteristics:

- Reamers possess multiple cutting edges (3–8 teeth), offering superior guidance and stable cutting action;

- The absence of a cross-edge facilitates better cutting conditions;

- Smaller machining allowances permit shallower chip flutes and thicker drill cores, enhancing tool body strength and rigidity.

Reaming typically achieves tolerances of IT11 to IT10 and surface roughness Ra of 12.5 to 6.3.

Reaming is commonly used for holes smaller than Image.

When drilling larger holes (D ≥ 30 mm), a small drill bit (0.5–0.7 times the hole diameter) is often used for pilot drilling, followed by reaming with an appropriately sized reamer.

This approach improves hole quality and production efficiency.

Reaming can also create countersunk holes and flat surfaces using specialized reamers with guide pins for hole alignment.

Reaming

In production, people widely use reaming as a finishing method for holes.

For smaller holes, reaming is a more economical and practical machining method compared to internal cylindrical grinding and precision boring.

Reamers

Reamers are generally classified into hand reamers and machine reamers.

Hand reamers feature a straight shank with a longer working section, providing better guidance. They come in two structures: solid-body and adjustable-diameter.

Machine reamers have two structures: shank-type and sleeve-type. Reamers can process not only circular holes but also tapered holes using taper reamers.

Reaming Process and Applications

Excessive reaming allowance increases load, dulls cutting edges, and reduces surface quality and dimensional accuracy.

Insufficient allowance fails to remove tool marks from preceding operations, thereby negating quality improvement.

Typically, rough reaming allowances range from 0.35 to 0.15 mm, while finish reaming allowances range from 0.15 to 0.05 mm.

Operators perform reaming at low speeds (v < 8 m/min for HSS reamers on steel and cast iron) to prevent built-up edges.

Feed rate depends on the hole diameter: larger holes require higher feed rates.

For high-speed steel reamers machining steel and cast iron, feed rates are typically 0.3–1 mm/rev.

Use appropriate cutting fluid during reaming to cool, lubricate, flush chips, and prevent built-up edges.

Compared to grinding and boring, reaming offers higher productivity and easier hole accuracy assurance;

However, reaming does not correct positional errors in the hole axis, so preceding processes must ensure hole positioning accuracy.

Reaming is unsuitable for machining stepped holes or blind holes.

Reamed hole dimensional accuracy typically ranges from IT9 to IT7, with surface roughness Ra generally between 3.2 and 0.8.

For medium-sized holes with higher precision requirements (e.g., IT7 grade), the drill-ream-tap process is a typical manufacturing solution.

Boring

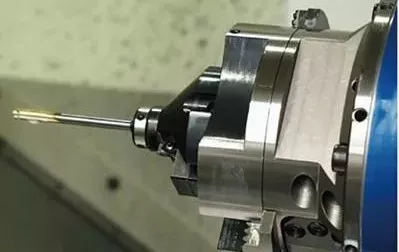

Boring is a machining method that enlarges pre-drilled holes using cutting tools. One can perform boring operations on either boring machines or lathes.

Boring Methods

Three distinct boring approaches exist:

- Workpiece rotation with tool feed movement

This method predominates in lathe boring.

Hole centerline aligns with the workpiece axis; roundness relies on spindle rotation, axial errors on tool-feed accuracy.

This method is suitable for holes requiring coaxiality with the outer cylindrical surface.

- During boring, the spindle rotates the tool while the worktable feeds the workpiece.

- Tool rotation with feed motion: In this boring method, the tool overhang length varies, causing corresponding deformation.

The bore diameter is larger near the headstock and smaller farther from it, resulting in a tapered bore.

Longer tool overhang increases spindle bending, distorting the hole axis; this method suits only relatively short holes.

Diamond Boring

Diamond boring uses small cuts, low feed, and high speed to achieve IT7–IT6 accuracy and Ra 0.4–0.05 surface finish.

Originally performed with diamond boring tools, diamond boring now commonly employs carbide, CBN, and synthetic diamond tools.

Primarily used for machining non-ferrous metal workpieces, it can also process cast iron and steel components.

Typical cutting parameters for diamond boring are:

- Depth of cut: 0.2–0.6 mm for rough boring, 0.1 mm for finish boring;

Feed rate: 0.01–0.14 mm/rev; Cutting speed: 100–250 m/min for cast iron, 150–300 m/min for steel, 300–2000 m/min for non-ferrous metals.

High-accuracy diamond boring requires a rigid, precise machine with angular-contact or hydrostatic spindle bearings and balanced high-speed parts.

Additionally, the feed mechanism’s motion must be exceptionally smooth to ensure the worktable performs stable, low-speed feed movements.

Diamond boring delivers high-quality, efficient finishing for precision holes like engine cylinders, piston pins, and spindle bores in mass production.

However, note that when machining ferrous metals with diamond boring, machinists may use only carbide or CBN boring tools.

Diamond tools are unsuitable because the carbon atoms in diamond have a strong affinity for iron group elements, resulting in low tool life.

Boring Tools

Boring tools can be classified into single-edge and double-edge types.

Process Characteristics and Applications of Boring

Compared with the drill-ream-tap process, boring avoids tool size limitations for hole diameters.

Boring corrects original hole-axis deviations in multiple passes while maintaining high positional accuracy with locating surfaces.

Boring’s low rigidity and thermal issues lower quality and efficiency compared to external turning.

In summary, boring offers a broad processing range, capable of machining holes of various sizes and precision grades.

For large-diameter holes and hole systems demanding high dimensional and positional accuracy, boring is nearly the only viable method.

Boring achieves IT9–IT7 accuracy with Ra , can be done on various machines, and is widely used; jigs often boost efficiency in high-volume production.

Honing Holes

Honing Principle and Honing Heads

Honing is a finishing process that uses a honing head equipped with abrasive strips (oilstones) to refine hole surfaces.

In honing, the stationary workpiece is machined by a spindle-driven honing head moving in a reciprocating linear motion.

During honing, abrasive strips press the workpiece, removing a thin layer and creating an intersecting mesh pattern.

Operators must set the honing head’s RPM as a prime multiple of its stroke rate to avoid overlapping paths.

The intersection angle 𝛳 of the honing trajectory relates to the reciprocating velocity va and circumferential velocity vc of the honing head.

The magnitude of angle 𝛳 affects both machining quality and efficiency.

Typically, 𝛳 = 40–60° is used for rough honing, while for finish honing, 𝛳 is selected.

Use sufficient cutting fluid in honing to remove chips, reduce heat, and improve machining quality.

Extend the honing bar stroke beyond the bore ends to ensure uniform machining.

Operators use a floating connection between the honing head and spindle to ensure uniform allowance and reduce spindle errors.

Operators can adjust the honing head’s abrasive strip radially using manual, pneumatic, or hydraulic systems.

Process Characteristics and Applications of Honing

- Honing achieves high dimensional and geometric accuracy, with machining precision reaching IT7 to IT6 grades.

Hole roundness and cylindricity errors can be controlled within specified ranges.

However, honing does not improve the positional accuracy of the machined hole.

- Honing achieves high surface quality with surface roughness Ra of 0.2–0.025 μm.

The depth of the surface metal’s altered defect layer is extremely shallow (2.5–25 μm).

- Compared to grinding speeds, the peripheral speed of honing heads is relatively low (vc = 16–60 m/min).

Despite large contact and high reciprocating speed (va = 8~20 m/min), honing achieves high productivity.

Honing is widely used in mass production for machining engine cylinder bores and precision holes in various hydraulic devices.

The typical bore diameter range is 100 mm or larger, and it can process deep holes with aspect ratios exceeding 10.

However, honing is unsuitable for machining holes in non-ferrous metal workpieces with high plasticity, nor can it process keyway holes, spline holes, etc.

Reaming

Reaming and Reamers

Reaming is a high-productivity finishing method performed on reaming machines using specialized reamers.

Reaming machines are categorized into horizontal and vertical types, with horizontal machines being the most common.

During reaming, the reamer performs only low-speed linear motion (the primary motion).

Typically, no fewer than three teeth of the broach should engage simultaneously;

Otherwise, unstable broaching may cause ring-shaped ripples on the workpiece surface.

To prevent excessive broaching force from fracturing the broach, no more than 6–8 teeth should engage at any given time during operation.

Three distinct broaching methods exist, described below:

- Layer-by-Layer Broaching

This method involves sequentially removing the workpiece’s machining allowance layer by layer.

To facilitate chip breaking, the teeth feature interlocking chip-breaking grooves.

Broaches designed for layer-by-layer broaching are termed standard broaches.

- Block-type broaching removes each metal layer using interlocking teeth sets (usually 2–3 teeth per set).

Each tooth removes only a portion of one layer. Broaches designed for block-type broaching are called rotary-cut broaches.

- Combined Broaching This method combines the advantages of both layered and segmented broaching.

The roughing section employs segmented broaching, while the finishing section uses layered broaching.

This approach reduces broach length, enhances productivity, and achieves superior surface quality.

Broaches designed for combined broaching are called combined broaches.

Process Characteristics and Application Scope of Hole Reaming

- Reamers are multi-edge tools capable of sequentially completing roughing, finishing, and honing operations in a single stroke, delivering high production efficiency.

- Hole reaming accuracy primarily depends on reamer precision.

Under typical conditions, hole accuracy can reach IT9 to IT7, with surface roughness Ra ranging from 6.3 to 1.6 μm.

- During broaching, the workpiece is positioned by the hole itself (the broach’s leading edge serves as the locating element).

This method makes it difficult to ensure the mutual positional accuracy between the hole and other surfaces.

Operators broach the hole first, then machine other surfaces using it as a reference.

- Broaches can machine not only circular holes but also shaped holes and spline holes.

- Reamers are fixed-size tools with complex geometries and high costs, making them unsuitable for large-diameter holes.

Operators use reaming for through-holes in small-to-medium parts (Ф10–80 mm, depth ≤5× diameter).

Conclusion

Machining internal holes presents unique challenges that far exceed those of external cylindrical surfaces, requiring careful management of tool rigidity, thermal distortion, and chip evacuation. From drilling and reaming to boring, diamond boring, honing, and broaching, each process offers distinct advantages and limitations, balancing efficiency, accuracy, and surface quality to meet specific production needs.

Drilling provides high material removal rates but limited precision, while reaming enhances diameter accuracy and surface finish without correcting positional errors. Boring corrects hole-axis deviations and achieves higher accuracy, yet tool rigidity and thermal effects remain critical concerns. Diamond boring and honing elevate precision and surface quality to IT7–IT6 levels, making them indispensable for mass-produced precision components such as engine cylinders, piston pins, and hydraulic devices. Broaching and advanced reaming techniques further expand the capability to produce complex hole geometries with high repeatability and efficiency.

Ultimately, mastering the selection, setup, and application of each hole-machining method ensures consistent precision, optimal surface quality, and efficient production. Understanding the strengths and constraints of these processes empowers operators and engineers to achieve reliable, high-quality internal holes, even in challenging workpieces and demanding manufacturing environments.