Milling machines are widely used in road maintenance to remove asphalt markings and level surfaces in workshops, docks, and parking lots.

A milling machine consists of an engine, frame, control system, and a drum that mills roads using rotating cutters.

Cutter head performance affects machine life, while environment, operation, material, and improper selection or cooling accelerate tool wear.

Tungsten carbide cutters resist wear but still degrade; this study examines their wear to improve design, durability, and cost efficiency.

Structure of the Milling Machine

As key pavement rehabilitation equipment, milling machines use tools to cut the ground surface during operations.

Driven by a power transmission system, the milling machine rotates its shaft, enabling cutting tools to perform milling tasks.

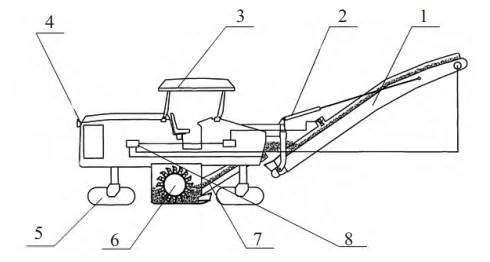

Figure 1 shows a milling machine with a conveyor, hydraulics, crawler, and a drum holding 80–120 tungsten carbide tools.

The crawler, driven by an electric motor and supported by wheels, enables the milling machine to move freely on roads.

The milling machine mills the road at a set depth, conveying material onto trucks via the loading section and discharge conveyor.

1—Discharge conveyor; 2—Adjustment hydraulic cylinder; 3—Operator cab rain cover;

4—Rear radar; 5—Crawler travel mechanism; 6—Milling drum assembly;

7—Primary feed section; 8—Drive unit

Mathematical Modeling of Force Application and Wear on Milling Drum Cutters

During high-speed operation, the milling drum cutters perform upward cutting on the road surface.

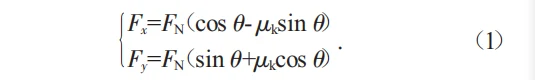

Figure 2 shows the milling drum structure, where welded cutter holders hold removable tools that rotate at high speed to cut the pavement.

During cutting, material is conveyed to trucks, and tool wear is modeled using bulk material dynamics.

According to Newton’s Second Law:

Where:

Fx is the horizontal component of the resultant force acting on the cut bulk material, N;

Fy is the vertical component of the resultant force acting on the cut bulk material, N;

FN is the normal force acting on the bulk material particles, N;

θ is the pitch angle of the cutting tool’s connected spiral blades, (°);

μk is the coefficient of kinetic friction between the blades and the particles.

Equation (1) shows that upward cutting increases tool wear, as higher speed, depth, and material hardness raise tool forces.

Analysis of Milling Drum Tool Wear Patterns

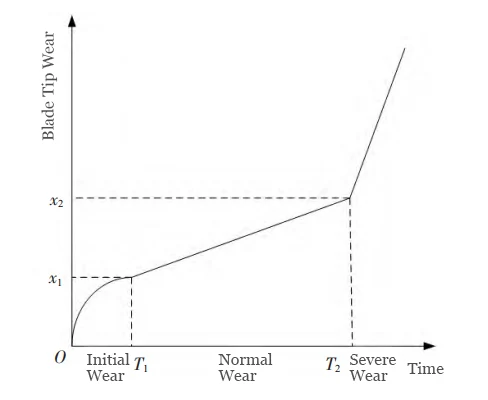

Under normal operation, tool wear mainly comes from material reaction forces. Helical blades experience impact and primarily abrasive wear, with the wear curve shown in Figure 3.

Figure 3 shows tool wear in three stages—initial, normal, and severe—reflected by cutting edge wear over time.

At startup, wear rises rapidly in the initial stage, then slows, reaching zero at T1, marking stable wear.

The period from time T1 to T2 represents the normal wear phase, during which the wear of the milling drum tools reaches equilibrium.

High-strength tool surfaces mill aggregates quickly; cutting edge wear grows linearly with time, reaching a maximum of x2.

From T2, the tool enters rapid wear as its coating fails, signaling replacement, with wear rate rising quickly.

To extend tool life, operators should limit milling to the stable wear phase and optimize tool design for stable drum operation.

Optimization of Milling Drum Cutter Structure

Milling drum cutters wear from road impact; an umbrella-shaped edge and 18 mm spacing reduce wear and extend tool life.

Composite tips with a hard outer layer and tough core extend tool life by cushioning impacts and reducing wear.

Structural improvements prevent secondary abrasion and impacts, reducing wear and extending milling drum cutter life.

The research conclusions provide valuable reference for future innovative designs of milling machines.

Conclusion

This study analyzed milling drum tool wear, examining structure, principles, forces, and mechanics, and derived wear curves for all stages.

Tool life is extended by a conical umbrella cutting edge and 18 mm tool spacing, reducing impact and secondary wear. Optimized tip material combines hard exterior with tough core, preventing chipping and prolonging normal wear.