Stainless steel, a chromium-rich alloy, is renowned for its exceptional resistance to corrosive environments like air, water, saltwater, and acids. However, machining stainless steel presents significant challenges. Its high plasticity, strong diffusion properties, and tendency to form a hardened layer increase cutting difficulty and accelerate tool wear.

Current Research Landscape

Understanding Cutting Heat

Traditional machining methods struggle to process high-performance materials like stainless steel efficiently and with high quality. This results in low production yields and inefficient processes, preventing these materials from reaching their full potential. To address this, experts developed high-intensity arc machining. This new technique offers a promising, efficient, and economical solution for surface processing.

Insights into Tool-Chip Friction

Friction-induced heat and shear deformation primarily influence the tip friction zone during cutting. This leads to complex chip friction patterns on the tool’s rake face, including sliding, bonding, and transitional friction. Recent research has produced a refined tip friction model. This model incorporates a “material transition layer” within the coupled friction zone, which offers a more comprehensive understanding of the complex friction phenomena at the tool tip.

Unraveling Martensitic Transformation

During stainless steel processing, stress, strain, and heat trigger a non-diffusional phase transformation from austenite to martensite. This transformation involves a shear process and generates nano and ultrafine particles. Experiments show that high strain rates accelerate martensitic transformation, which increases the material’s tensile deformation and bending radius. Furthermore, high temperatures significantly promote tensile strain-induced martensitic transformation compared to low temperatures.

Current Challenges

Addressing Cutting Heat Modeling Limitations

The most common method for calculating cutting heat is the helical tooth motion heat source theory. However, this method simplifies the main shear region to a thin, non-thick section, which doesn’t accurately represent the shear band’s true thickness. The volume transfer heat source method attempts to compensate for this, but it still simplifies the main shear plane into two equally thick parallel regions.

Factors Affecting Surface Roughness

High-intensity arc machining is efficient, but it can cause minor surface defects. These defects, such as hardened layers and cracks, significantly impact subsequent processing and component longevity. This is especially true given the increasing demand for precision in modern manufacturing. Therefore, ensuring workpiece quality requires addressing these surface defects starting from the semi-finishing stage. This is a complex endeavor involving numerous interacting factors.

Gaps in Tool-Chip Friction Models

Traditional chip friction models only include composite and sliding friction zones. Newer shoulder friction analysis models introduce a transition friction zone for a smoother description. However, these models have not yet quantified the role of the experimentally observed, albeit minuscule, “material conversion layer” within the coupled friction zone. This layer’s impact still awaits integration into current cutting-edge friction models.

Martensitic Transformation on Machined Surfaces

During cutting, austenitic stainless steel transforms into two types of martensite: body-centered cubic and high-density hexagonal. However, the scientific community still lacks a definitive, unified theory regarding the presence of an intermediate phase and the intricate mechanisms of this transformation. Therefore, this paper uses experimental methods to analyze how cutting parameters influence martensitic phase transformation in stainless steel. It specifically considers the application background of stainless steel in nuclear power.

Experimental Results and Analysis

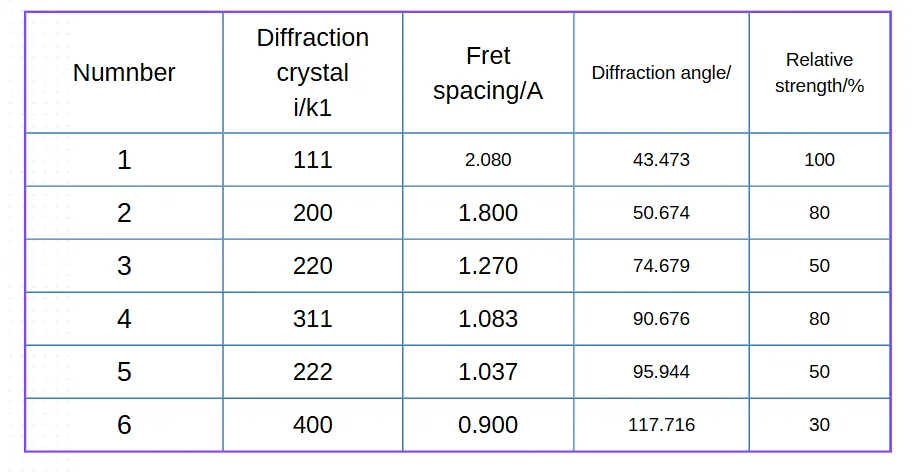

Tables provide insights into the diffraction standard data for austenite and both types of martensite. This data includes their respective diffraction crystal planes (hkl), diffraction angle (2θ), crystal plane spacing (d), and corresponding relative diffraction peak intensities.

Conclusion

Future research in stainless steel surface treatment should prioritize improving processing methods. The goal is to enhance surface quality, hardness, and precision, aiming for highly efficient and precise machining. This will involve expanding current theoretical models and numerical calculations for cutting heat, chip friction, cutting force, residual stress, and martensitic phase transformation into three-dimensional conditions. This expansion will lead to more comprehensive prediction models and theoretical analyses.