CNC lathes are highly integrated opto-mechatronic devices. They comprise fundamental structural components such as the bed, base, worktable, and spindle housing.

In addition, they include core functional modules such as the spindle unit, ball screw, and tool turret.

To enable continuous multi-process machining, manufacturers equip CNC lathes with turret devices that automatically switch tools, allowing different operations to connect seamlessly.

Engineers categorize turrets into three primary drive types: electric, hydraulic, and servo-driven.

As the core functional component of the lathe, the turret is an indispensable key machine tool accessory.

Designers mount the tools directly within the machining zone.

Operators can rotate and switch them on the turret, enabling immediate production deployment without disassembly.

Overview of CNC Lathe Turret Technology

Electric Turret

Powered by an electric motor, the electric turret features a simple structure, low manufacturing cost, and straightforward daily maintenance.

It fully meets conventional machining requirements, particularly suited for production environments with high tolerance for precision and budget constraints.

Its drawbacks include insufficient positioning accuracy and susceptibility to vibration during high-speed tool changes, which can compromise machining precision.

Additionally, its power output has an upper limit, making it difficult to handle the load intensity required for heavy-duty cutting operations.

Hydraulic Turret

1. Structure and Working Principle

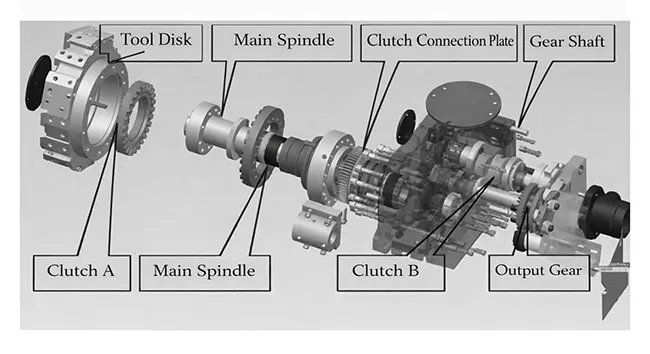

The exploded view diagram of the cam-type hydraulic turret is shown in Figure 1.

It accommodates multiple tool specifications, with optional configurations including 6, 8, 10, or 12 tools.

A hydraulic motor powers the core drive of the hydraulic turret.

The cylinder piston locks and releases the tool disc, while an internal cam mechanism drives its rotation.

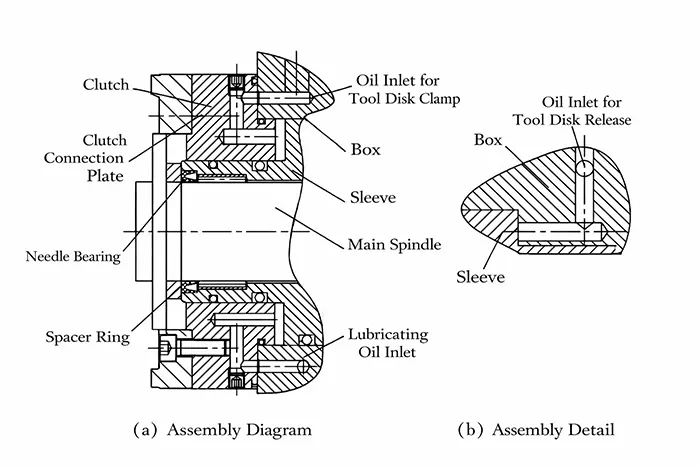

The assembly schematic of key components for the hydraulic turret is shown in Figure 2.

Engineers fix one clutch to the housing and integrate the other with the tool turret.

They mount the tool turret on the spindle. When the clutch engages, it keeps the tool turret stationary.

When the clutch disengages, it allows the tool turret to rotate.

The axial movement and rotational motion of the spindle determine the locking state and rotational status of the tool turret.

Upon receiving a tool change command from the CNC, the hydraulic turret activates the tool turret ejection solenoid valve.

After the turret is released, hydraulic oil enters the system through the inlet port.

The oil flows through internal passages within the housing, reaching the right chamber of the piston and driving it outward.

Technicians install a spacer ring at each end of the piston, securing the right spacer ring with a locknut.

As the piston moves outward, it drives the spindle to move synchronously outward via the left spacer ring.

This disengages the two ratchet clutches connecting the housing and tool turret, allowing the turret to select tools in response to rotation commands.

Lock the cutterhead, and the cutterhead lock oil inlet supplies oil.

The system delivers hydraulic oil to the clutch coupling plate area.

The oil enters the left chamber of the piston through the coupling plate, driving the piston to retract inward.

The piston drives the spindle to move inward synchronously via the right spacer ring, locking and securing the cutterhead.

Once the system locks the cutterhead in place, it executes the preset machining instructions.

2. Advantages and Disadvantages of Hydraulic Tool Towers

Hydraulic tool towers deliver powerful output, making them suitable for heavy-duty machining.

They excel in applications with less stringent precision requirements, particularly for roughing operations and heavy-cutting tasks demanding significant cutting forces.

Capable of withstanding high loads, they maintain stable performance when machining large or hard materials.

However, the inherent characteristics of hydraulic systems impose several limitations.

Hydraulic fluid leaks can cause environmental pollution and safety hazards, increasing maintenance costs.

Hydraulic systems exhibit relatively slow response times in low-temperature environments, reducing machining efficiency.

They are unsuitable for scenarios requiring rapid tool changes and high-precision positioning.

As modern CNC machining increasingly pursues high precision and efficiency, engineers are gradually limiting the application of hydraulic turrets.

Servo Turret

A servo motor powers the servo turret, and a high-precision absolute encoder provides real-time position feedback.

It features three prominent characteristics: high precision, rapid speed, and stable operation.

With exceptional dynamic response capability, it executes machining commands swiftly, significantly shortening processing cycles and markedly enhancing production efficiency.

The servo turret also offers advantages of easy maintenance and extended service life, fully meeting the demands of high-precision, high-efficiency machining.

It is widely applied in mid-to-high-end CNC lathe applications, with its technical advantages particularly prominent when machining high-precision complex parts.

1. Servo Turret Hardware

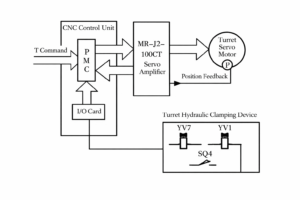

The block diagram of the servo turret hardware system is shown in Figure 3.

After receiving G-code instructions from external sources, the CNC control unit coordinates the overall process using a programmable multi-axis controller (PMC).

The PMC transmits control signals to the servo amplifier, which amplifies these signals to drive the servo motor.

Simultaneously, it acquires position feedback signals to ensure precise positioning of the turret.

The system also integrates an I/O card responsible for processing input and output signals, which may involve commands from the operator panel or feedback data reflecting the machine tool’s status.

Encoders on the turret transmit actual position information to the servo amplifier, establishing a closed-loop control system to enhance the accuracy and repeatability of tool-changing operations.

The turret hydraulic locking mechanism comprises two solenoid valves, YV7 and YV1, along with a hydraulic lock switch SQ4.

These solenoid valves control the hydraulic circuit’s on/off state to drive the turret’s locking or unlocking actions.

The SQ4 switch detects whether the turret locks securely in position and transmits this status signal to the CNC control unit, ensuring that machining operations remain safe and reliable.

2. PMC Control Principle

In the control system of a CNC lathe’s servo turret, interface signals play a pivotal role as the core elements enabling precise control.

Interface signals enable the CNC control unit, PMC, servo amplifier, and turret servo motor to communicate effectively.

The CNC control unit exchanges data with the servo amplifier via the PMC.

The PMC generates corresponding control signals based on received command signals (e.g., tool change commands).

The system then transmits these signals through the interface to the servo amplifier, which drives the turret servo motor to perform the tool change action.

Simultaneously, encoders on the turret return position feedback signals to the PMC, forming a closed-loop control system to ensure precise turret positioning.

The status of the hydraulic locking mechanism is likewise fed back to the PMC via interface signals for monitoring the turret’s locking condition.

These interface signals encompass not only electrical signals but may also involve hydraulic signals, collectively forming a complex control network that ensures the coordinated operation of the entire turret control system.

Utilizing these interface signals, the PMC precisely regulates each movement of the turret to accomplish an efficient and accurate tool change process.

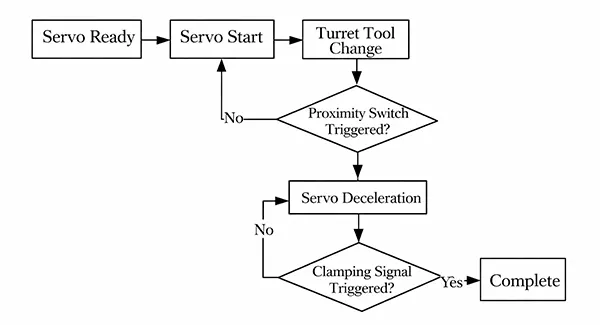

The PMC control flow diagram is shown in Figure 4. PMC control serves as the core of the CNC lathe servo turret control system, responsible for precisely coordinating and managing turret movements.

Upon receiving the tool change command (TF: X274 set to 1) from the CNC, the PMC system initiates the tool change process.

It reads the target tool position (R335) transmitted via the T code from the CNC and compares it with the turret’s current actual position (R7722).

If the two positions do not match, it activates the servo shutdown command (∗SVF: R7552.0 set to 1) to ensure system safety.

Controls the turret to execute the release action (YV1: Y11 set to 1). Automatically calculates the optimal path for the turret to rotate to the target position.

Sends the calculated target position command to the servo amplifier (R335 → R7554).

Based on preset servo parameters (e.g., gear ratio, speed), the PMC issues a start command to the servo amplifier (ST: R7553.0 set to 1).

The servo motor then drives the turret rotation according to the command.

Upon detecting the turret reaching the target position, the servo system feeds back a position-reached signal (JST: R7720.E set to 1) and updated current tool position data (R7722) to the PMC.

After verifying the position accuracy, the PMC cancels the servo start signal (ST: R7553.0 set to 0).

Issues a turret lock command (YV7: Y10 set to 1). After detecting and confirming the turret lock status (SQ4: X10 set to 1), the PMC releases the servo shutdown state (SVF: R7552.0 set to 0).

Feedback the tool change completion signal to the CNC (T.FIN: Y2A4 set to 1). At this point, the entire tool change operation is completed.

Through this control mechanism, the PMC ensures the automation and intelligence of turret operations, enhancing the machining efficiency and quality of CNC lathes.

Comparison of Servo Turrets and Hydraulic Turrets

As the manufacturing industry continually pursues higher precision, efficiency, and automation levels, the performance of CNC lathe turret systems determines machining quality and production efficiency.

Engineers aim to achieve substantial improvements in machining accuracy and enable rapid, precise tool changes.

They must also ensure equipment stability and reliability during continuous operation.

Reducing downtime and maintenance costs is another important goal. For these reasons, upgrading existing turret systems has become a necessary measure.

A comparison of servo turrets and hydraulic turrets is presented in Table 1.

Advanced servo turret technology not only enhances turret motion control and boosts machining efficiency but also meets the stringent performance demands of complex part machining.

This comprehensively elevates the overall performance of CNC lathes, making them better suited to the production requirements of modern manufacturing.

| Performance Comparison | Servo Turret | Hydraulic Turret |

|---|---|---|

| Tool Change Speed | The servo motor serves as the core driving unit and features high-speed rotation characteristics. Its speed can be precisely adjusted through preset parameters, allowing operators to flexibly control the equipment’s operating status. | Driven by a hydraulic system, the feed action is relatively slow, making the tool change process difficult to control smoothly. |

| Positioning Accuracy | The servo motor provides high-precision position control. Combined with real-time feedback from positioning sensors, a coordinated control mechanism is formed, enabling accurate positioning control. | Fluctuations in oil quality and insufficient control accuracy of hydraulic components jointly limit the effective improvement of positioning accuracy. |

| Logic Control | The servo drive system uses programmable logic circuits to achieve control functions. Its architecture is open, operation is convenient, and it offers high flexibility. | The logic adjustment capability of the hydraulic system lacks flexibility. |

| Installation Conditions | The equipment adopts a unified interface design, and its environmental performance spans the entire product life cycle. | The hydraulic system contains a large number of connecting pipelines and components. Installation is cumbersome, the operating environment is harsh, and overall operation faces severe challenges. |

| Stability | The servo motor is safe and stable, and the transmission mechanism is rigid and reliable, jointly ensuring stable system operation. | Speed variations during turret indexing are often related to hydraulic oil temperature fluctuations, and oil quality advantages directly determine the stability of equipment operation. |

Servo Turret Application Case Study

Signal Definition

Using the servo turret from Omori Machine Tools as an application case, this document provides a detailed explanation of the servo turret’s logic control process.

The control section requires customized design based on the structural characteristics of different machine tools to ensure precise execution of signal control and control logic.

The case study first defines the functions of each input/output (I/O) port.

These I/O ports include tool number position signals, mode switching signals, and servo turret lock/unlock detection sensor signals, which form the core of precise turret control.

Next, the turret workflow is planned, involving executing tool change commands, outputting TLOCK signals to lock the change process, and outputting M61 signals to initiate hydraulic release.

Finally, the implementation of the system tool-changing sequence describes the entire process from initiation to completion.

It includes critical steps such as verifying tool number position signals.

The system also activates hydraulic clamping and release signals and continuously monitors the locking status.

This process enhances tool-changing automation. It also ensures operational safety and reliability.

As a result, the system improves the overall performance and machining efficiency of the CNC lathe. Table 2 provides the signal definitions.

| System-side Signal | Turret Servo Drive-side Signal | Signal Definition |

|---|---|---|

| T04 | D04 Signal | Tool number position signal |

| T03 | D03 Signal | Tool number position signal |

| T02 | D02 Signal | Tool number position signal |

| T01 | D01 Signal | Tool number position signal |

| TL + | D17 | Mode switch 1 |

| TL − | D18 | Mode switch 2 |

| T06 | S8 | Servo turret clamp/unclamp detection signal |

| T05 | D05 | Tool number position signal corresponding to servo drive |

| M59 | Y1a | Turret hydraulic clamping signal |

| M61 | Y1b | Turret hydraulic unclamping signal |

| TLOCK | D16 | Servo enable |

Workflow

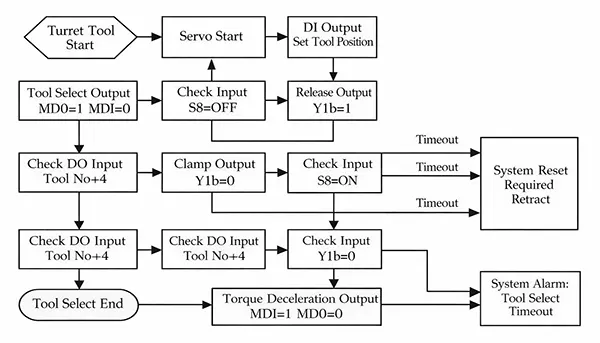

The tool change process diagram is shown in Figure 5.

The turret tool change process begins with tool selection initiation, servo activation, and setting the selected tool position via DI output.

When the system executes the release output, Y1b is set to 1, while simultaneously verifying whether input S8 is in the OFF state.

If S8 is OFF, the tool selection trigger output is executed, adjusting MD0 = 1 and MD1 = 0, and verifying that D0 input equals the selected tool number + 4.

Subsequently, the system performs the clamping output, adjusting Y1B to 0, while checking if S8 input is ON.

If S8 is ON, implement torque reduction output by setting MD1 = 1 and MD0 = 0.

Throughout this process, if any operation step times out, the system enters timeout handling, which may involve re-zeroing or triggering an alarm indicating tool change timeout.

This process ensures the automation and precision of turret tool change operations, enhancing the machining efficiency and reliability of CNC lathes.

Tool Change Sequence

Within the servo turret control system of a CNC lathe, the PMC serves as the core component, performing critical functions.

It processes commands from the CNC control unit and drives the turret to execute tool change operations.

The PMC communicates with the turret servo drive side via interface signals, which include elements such as tool number position, mode switching, and lock/unlock check sensing.

Its control principle involves performing logical analysis on these signals to ensure precise tool change operations.

When the tool change process initiates, the system issues a tool change command.

A TLOCK signal of 1 indicates that the system has locked the tool change operation.

The M61 signal is activated to 1, and the PMC monitors the T06 signal (i.e., the S8 servo tool holder lock/unlock check signal) to confirm the turret is in the correct state.

If the T06 signal is 0, the PMC sets TLP to 1 and TLN to 0 after a 100 ms delay, indicating the tool change operation is in the execution phase.

If the tool number positions indicated by signals T01 to T05 (corresponding to D01 to D05) do not match the current tool number position, the PMC triggers a timeout alarm mechanism.

During tool change, when the PMC’s M59 (Y1a) signal is 1, it triggers the turret hydraulic clamping mechanism to ensure the tool is securely held.

The PMC sets M61 (Y1b) to 0, initiating the turret hydraulic release function to prepare for tool change.

PMC then continuously monitors the T06 signal. Once this signal goes high, indicating the turret has successfully locked, PMC sets both TLP and TLN signals to 1, completing the tool change action.

Finally, PMC sets TLOCK to 0, unlocking the tool change process and concluding the operation.

Conclusion

This technical solution upgrades a hydraulic turret to a servo turret and describes the structural composition of the servo turret.

It also describes the control principles of the Programmed Machine Control (PMC).

In addition, the system provides detailed specifications of the interface signals.

Practical case studies demonstrate the control logic and operational procedures of the servo turret, highlighting its significant advantages in improving the machining efficiency and reliability of CNC lathes.

With ongoing technological advancements, the application of servo turrets will propel CNC lathes toward higher precision and greater efficiency.