Soft jaws maximize repeatability in workpiece positioning, ensuring the machined part’s centerline perfectly aligns with the spindle’s centerline. Their flat surfaces also guarantee workpiece length accuracy.

Most importantly, soft jaws achieve maximum surface contact with the workpiece. This enables higher torque transmission while preventing workpiece damage—advantages hard jaws simply cannot match.

When fabricating soft jaws, pay attention to the following issues:

Material Selection for Soft Jaws

Here, “soft” refers to good machinability—it does not necessarily mean the material must be softer than the workpiece.

(For mass production, the hardness of soft jaws significantly impacts machining stability. Choosing a material harder than the workpiece not only extends the jaws’ service life but also positively affects machining stability.)

Selecting Soft Jaw Dimensions

Soft jaws must grip at least one-third of the workpiece length.

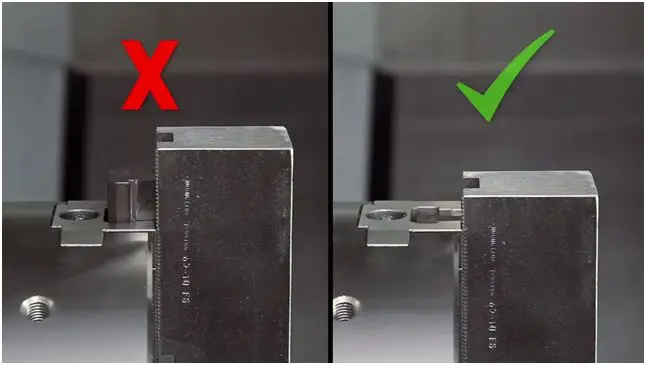

Mounting Position on Chuck

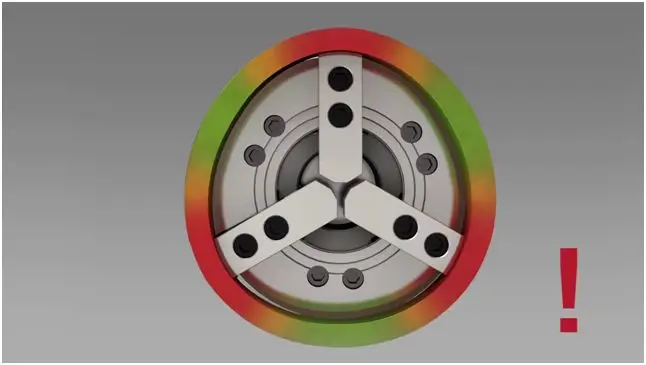

Any T-block exceeding the chuck’s maximum diameter is prohibited due to significant safety risks.

Adding Clearance Grooves

Ensures repeatable workpiece positioning.

Removing Burrs and Sharp Edges from Soft Jaws

Take extreme care to avoid hand injuries.

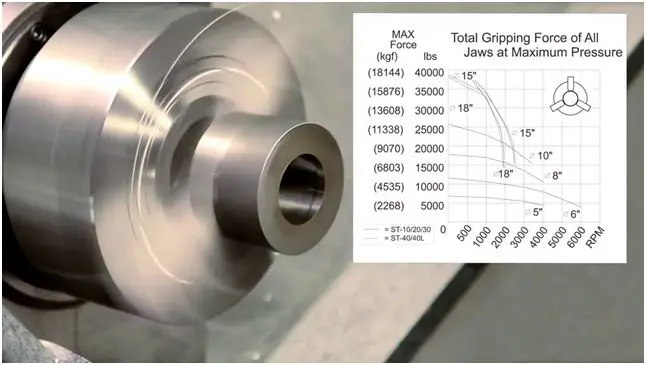

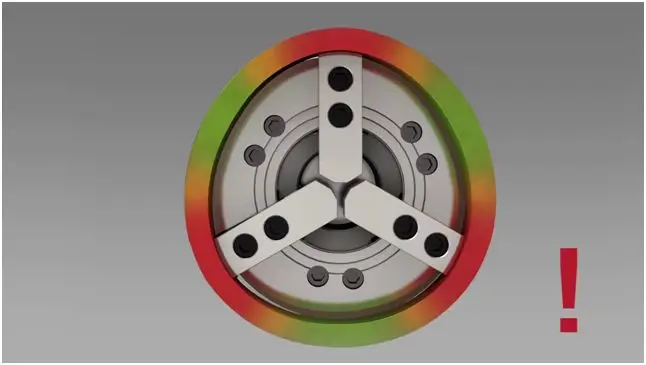

The following video demonstrates the impact of rotational speed on clamping force through practical testing.

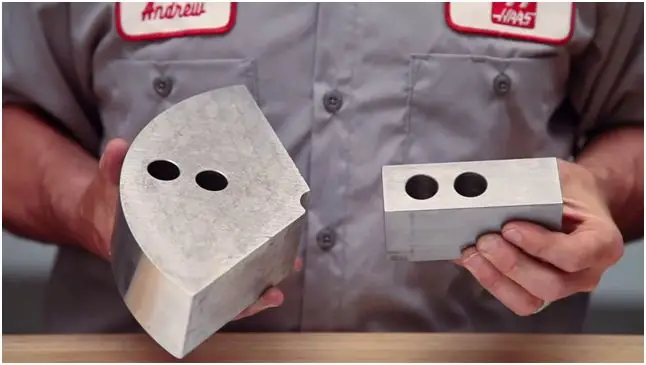

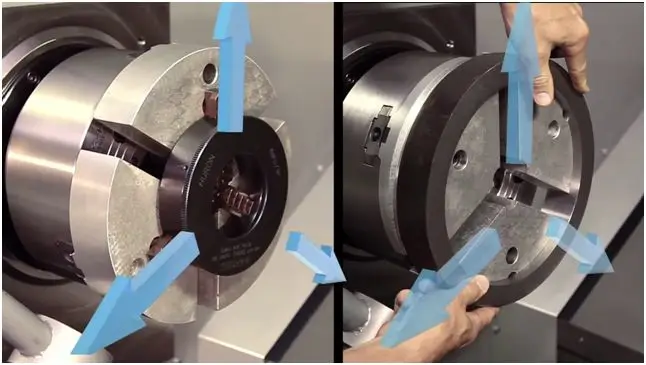

When machining thin-walled or ring-shaped workpieces, overcoming deformation is the primary challenge. Selecting the correct soft jaw type and appropriate chuck pressure is critical.

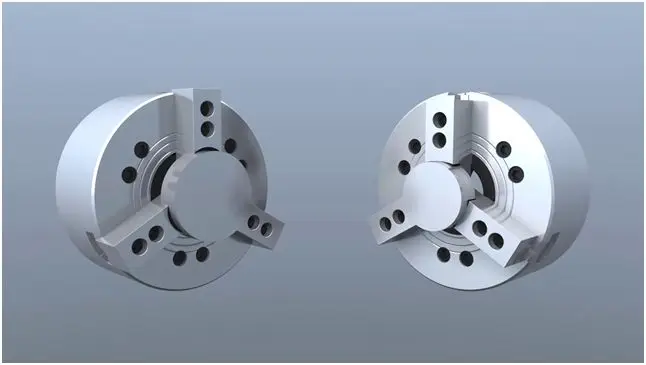

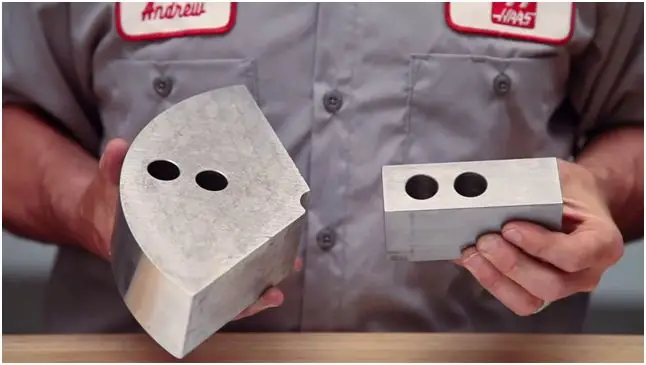

Under the same chuck pressure, fan-shaped soft jaws offer greater contact area and more uniform pressure, while standard soft jaws behave as follows:

The video shows workpiece deformation can vary tenfold under identical conditions, depending on jaw type. Both fan-shaped and standard soft jaws require re-machining due to excessive wear or part replacement.

During re-machining, first mark and number the soft jaws to be removed. This maximizes their usable life, while detailed labeling reduces misapplication risks.

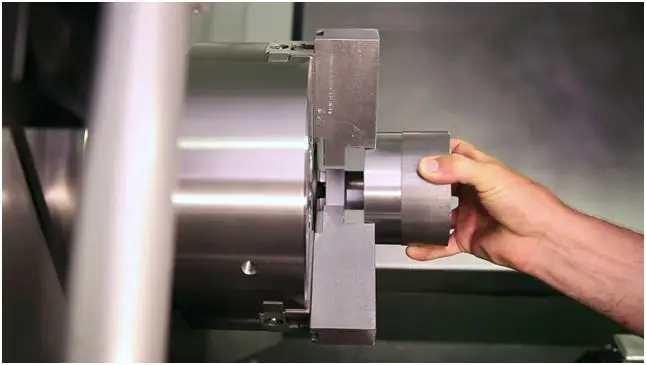

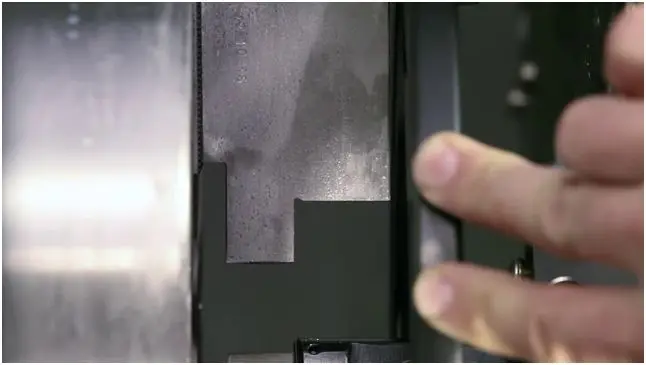

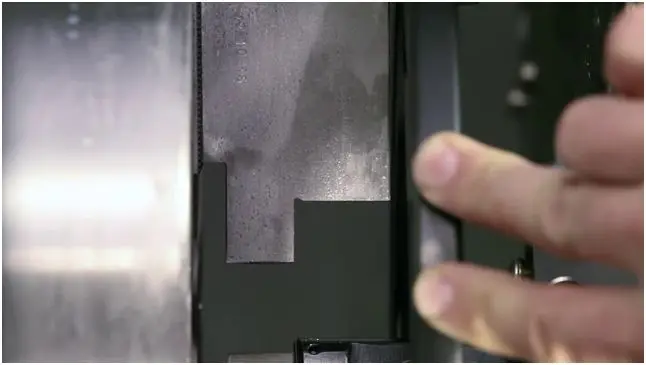

Next, select the appropriate re-machining tool: Typically, the left tool re-machines inner jaws, while the right tool handles outer jaws.

The following considerations apply to both manufacturing and refurbishing soft jaws:

- T-blocks must not exceed the chuck’s maximum diameter.

- Refurbishing pressure should approximate machining pressure, with the chuck positioned at its mid-travel range.

- Clamping force direction during refurbishing must align with machining clamping force.

- Monitor spindle speed during refurbishing.

- Add relief grooves to remove burrs and sharp edges.

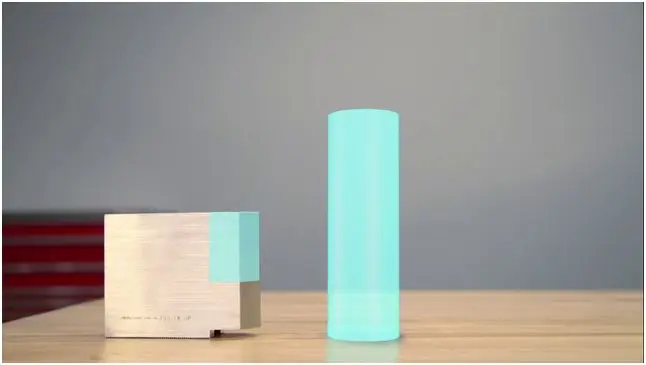

When neither standard tooling meets requirements, a specialized tooling component must be fabricated—such as machining the ring below to repair the outer jaw.

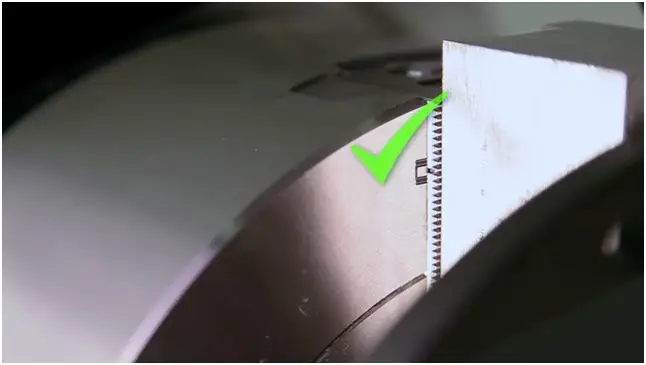

When machining parts with extended gripping sections, a gap may form between the workpiece and soft jaws, commonly termed a “flared gap.” This manifests as a visible space between the soft jaw’s top face and the workpiece.

The most effective solution is to machine a taper into the soft jaws. Measure the gap size with a feeler gauge and determine the clamping length. This allows calculation of the required taper angle.

Conclusion

Soft jaws play a pivotal role in precision machining by maximizing repeatability, ensuring accurate alignment between the workpiece and spindle, and providing consistent surface contact for optimal torque transmission.

Choosing the right material, dimensions, and mounting position, along with carefully controlling chuck pressure and clamping force, directly impacts machining stability and workpiece integrity.

Fan-shaped soft jaws offer superior contact area and pressure distribution, reducing deformation, while standard soft jaws still require careful handling and periodic re-machining.

Incorporating best practices—such as creating internal bores, adding clearance grooves, removing burrs, and properly labeling jaws—extends their service life and minimizes risks during machining or refurbishing.

Ultimately, mastering soft jaw selection, trimming, and maintenance ensures safer operations, higher accuracy, and more efficient machining, even for challenging thin-walled, ring-shaped, or extended-grip workpieces.

Proper attention to these details transforms soft jaws from simple fixtures into essential tools for precision, repeatability, and operational excellence.

Creating an Internal Bore Matching the Workpiece Diameter

Reduces the risk of workpiece damage.

Adding Clearance Grooves

Ensures repeatable workpiece positioning.

Removing Burrs and Sharp Edges from Soft Jaws

Take extreme care to avoid hand injuries.

The following video demonstrates the impact of rotational speed on clamping force through practical testing.

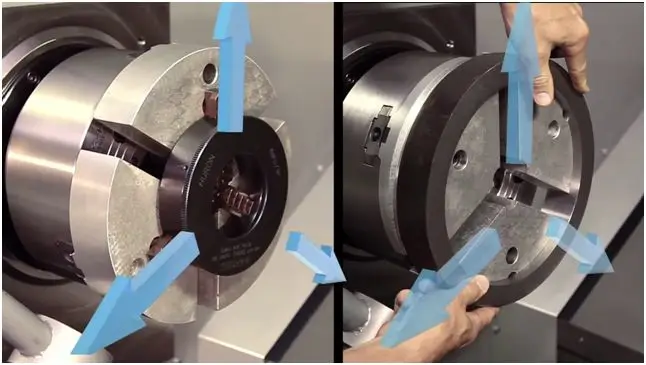

When machining thin-walled or ring-shaped workpieces, overcoming deformation is the primary challenge. Selecting the correct soft jaw type and appropriate chuck pressure is critical.

Under the same chuck pressure, fan-shaped soft jaws offer greater contact area and more uniform pressure, while standard soft jaws behave as follows:

The video shows workpiece deformation can vary tenfold under identical conditions, depending on jaw type. Both fan-shaped and standard soft jaws require re-machining due to excessive wear or part replacement.

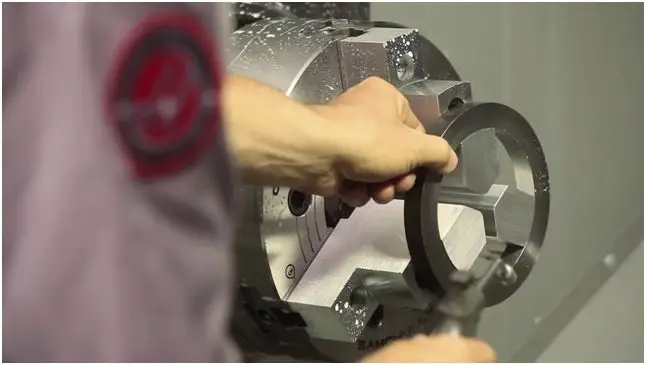

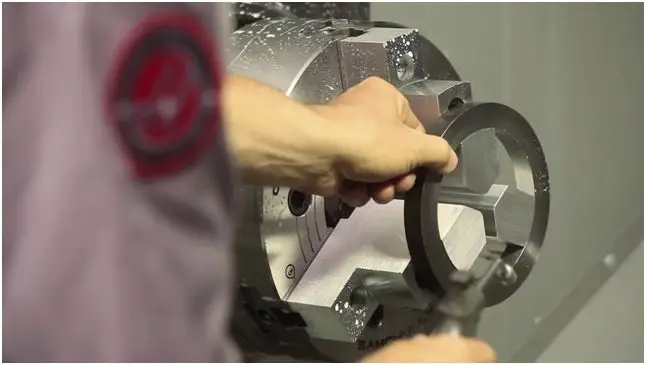

During re-machining, first mark and number the soft jaws to be removed. This maximizes their usable life, while detailed labeling reduces misapplication risks.

Next, select the appropriate re-machining tool: Typically, the left tool re-machines inner jaws, while the right tool handles outer jaws.

The following considerations apply to both manufacturing and refurbishing soft jaws:

- T-blocks must not exceed the chuck’s maximum diameter.

- Refurbishing pressure should approximate machining pressure, with the chuck positioned at its mid-travel range.

- Clamping force direction during refurbishing must align with machining clamping force.

- Monitor spindle speed during refurbishing.

- Add relief grooves to remove burrs and sharp edges.

When neither standard tooling meets requirements, a specialized tooling component must be fabricated—such as machining the ring below to repair the outer jaw.

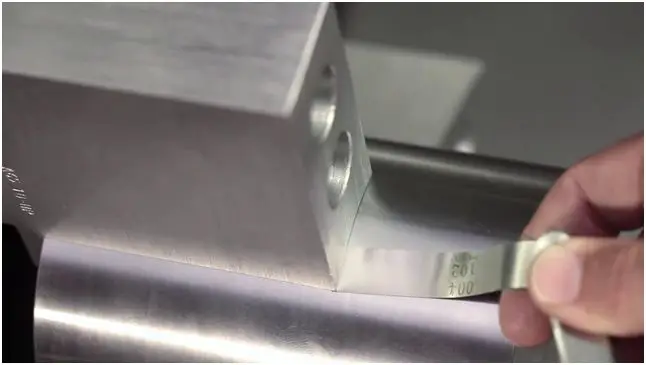

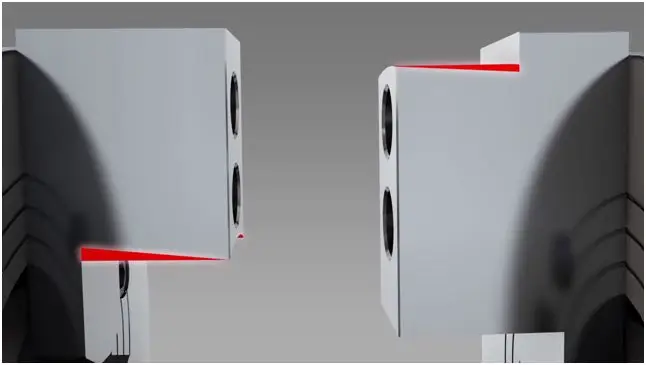

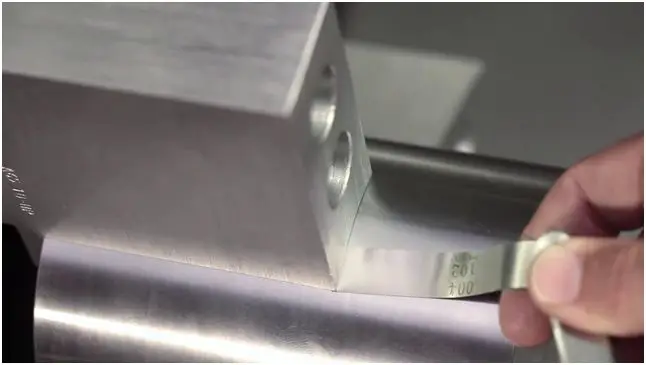

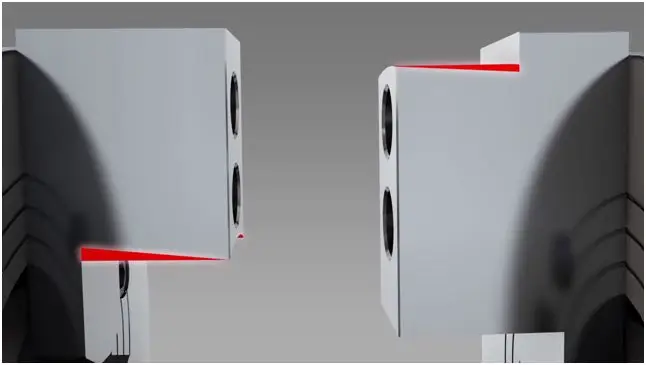

When machining parts with extended gripping sections, a gap may form between the workpiece and soft jaws, commonly termed a “flared gap.” This manifests as a visible space between the soft jaw’s top face and the workpiece.

The most effective solution is to machine a taper into the soft jaws. Measure the gap size with a feeler gauge and determine the clamping length. This allows calculation of the required taper angle.

Conclusion

Soft jaws play a pivotal role in precision machining by maximizing repeatability, ensuring accurate alignment between the workpiece and spindle, and providing consistent surface contact for optimal torque transmission.

Choosing the right material, dimensions, and mounting position, along with carefully controlling chuck pressure and clamping force, directly impacts machining stability and workpiece integrity.

Fan-shaped soft jaws offer superior contact area and pressure distribution, reducing deformation, while standard soft jaws still require careful handling and periodic re-machining.

Incorporating best practices—such as creating internal bores, adding clearance grooves, removing burrs, and properly labeling jaws—extends their service life and minimizes risks during machining or refurbishing.

Ultimately, mastering soft jaw selection, trimming, and maintenance ensures safer operations, higher accuracy, and more efficient machining, even for challenging thin-walled, ring-shaped, or extended-grip workpieces.

Proper attention to these details transforms soft jaws from simple fixtures into essential tools for precision, repeatability, and operational excellence.