Hard and brittle materials have become essential manufacturing materials for precision instruments and other structures.

High hardness and brittleness make these materials prone to microcracks, deformation, and fracture, rendering them difficult to machine.

Researchers are currently focusing on analyzing the machinability of hard and brittle materials.

Given the challenging machinability of these materials, prior research has predominantly focused on their machining processes.

Experts used 2D turning simulations to build a turning-force model for hard, brittle materials, using shear and friction angles to estimate dominant cutting forces.

We used low-temperature micro-abrasive jet machining to examine how parameters affect erosion quality and to identify highly erosion-resistant materials.

We selected tempered glass, used rotating ultrasonics to optimize micro-hole drilling parameters, and performed orthogonal tests to determine the best settings.

Experiments verify precise control, and force–roughness analysis provides a machining basis for hard–brittle materials.

We used optical glass to study tool wear and surface roughness in turning hard and brittle materials under different parameters.

Experimental Preparation and Design

Tests capture the cutting process and support optimization, and a semi-empirical force model was built and validated on a test bench.

The setup is shown in Fig. 1, using a CAK4085 CNC lathe, optical glass workpieces, and a VCMT160 tool.

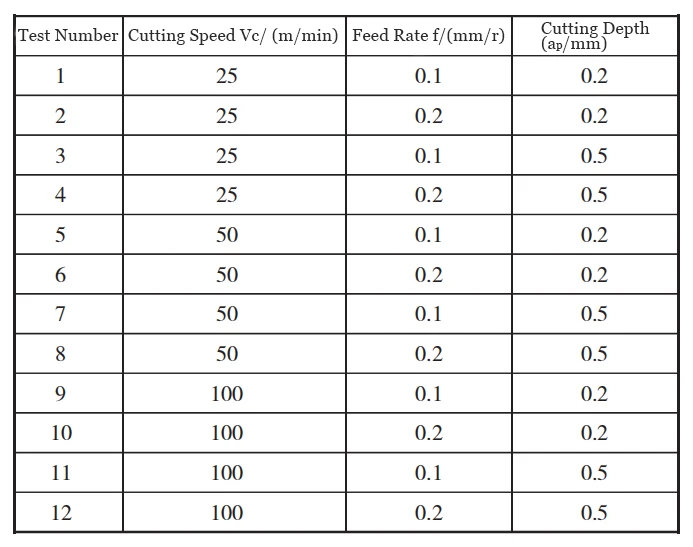

A FLIRT630sc imager and Kistler 5017A tester tracked tool wear and roughness. Twelve parameters were tested, with orthogonal results in Table 1.

Results Analysis

Before analyzing the results in detail, we first present an overview of the machining outcomes. The experiments captured variations in tool wear and surface roughness under different cutting parameters, providing a foundation for understanding the effects of feed rate, cutting speed, and depth of cut. The following sections discuss tool wear and surface roughness analyses in detail.

Tool Wear Analysis

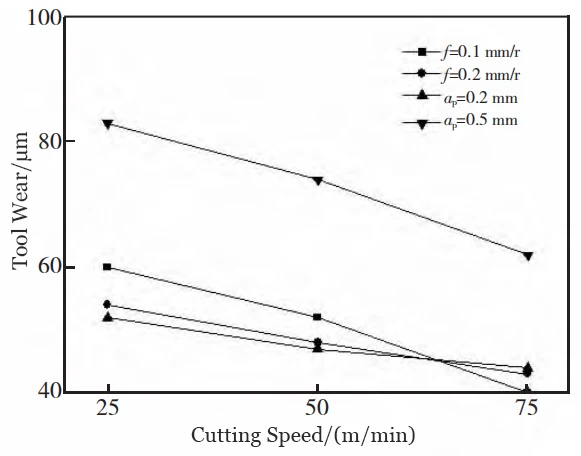

We examined tool wear using a VHX-2000C optical microscope, and Fig. 2 shows its variations under different cutting parameters.

The experiment shows that VB wear decreases as we increase cutting speed from 25 to 100 m/min, but rises with higher feed (0.1→0.2 mm/r) and depth (0.2→0.5 mm).

Higher cutting speeds reduce adhesion, boost heat dissipation, and even load, improving surface quality.

We observed that increasing feed slightly reduces tool wear below 75 m/min, but significantly increases wear above 75 m/min.

At low speed and small feed, wear is normal; a large feed increase raises temperature and accelerates tool wear.

The thin brittle specimen reaches ~2,000 r/min at rotational speeds above 75 m/min.

A large feed reduces friction and cutting force, increases shear angle, lowers heat, and minimizes tool wear.

However, as feed rate and cutting depth increase, the specimen undergoes accelerated shear deformation, generating significant localized heat at the cutting zone.

Deep cutting transfers excess energy to the tool, increasing wear and risking brittle fracture.

Surface Roughness Analysis

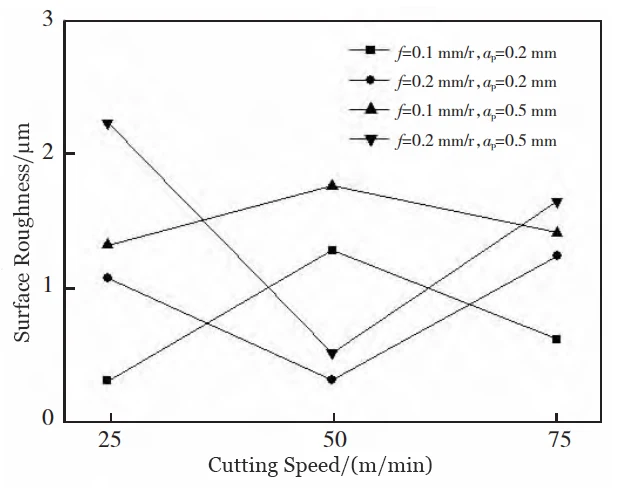

We measured and recorded the Ra surface roughness of each specimen after machining using the TR240 roughness tester, as shown in Figure 3.

Figure 3 shows that 0.1 mm/r feed yields a smoother surface than 0.2 mm/r, while 0.5 mm depth increases roughness versus 0.2 mm.

Due to high hardness and low toughness, chips form built-up edges on the tool, accelerating wear and increasing surface roughness.

High feed and deep cuts increase material removal, raising cutting forces and heat, which accelerates tool wear and worsens surface quality.

Conclusions

This study analyzes tool wear and surface roughness during turning of hard and brittle materials, yielding the following beneficial results:

Above 75 m/min, high-frequency rotation occurs; a large feed reduces friction, cutting force, and heat, mitigating tool wear.

A 0.1 mm/r feed yields smoother surfaces than 0.2 mm/r, 0.5 mm depth increases roughness, and high feed with deep cuts removes more material per unit time.